ISO 13485 Injection Molding Turnkey Solutions

High-performance Medical Molding Solutions

Optimold is a UK-based contract manufacturer specializing in high-precision injection molded plastic components for the medical and life sciences industries. Our capabilities include micro injection molding, two-material (2K) molding, and validation, with a strong focus on medical devices, ophthalmic components and drug delivery systems. In collaboration with their sister company, Micro Systems, Optimold enhances its offering with advanced micro mold design and manufacturing expertise.

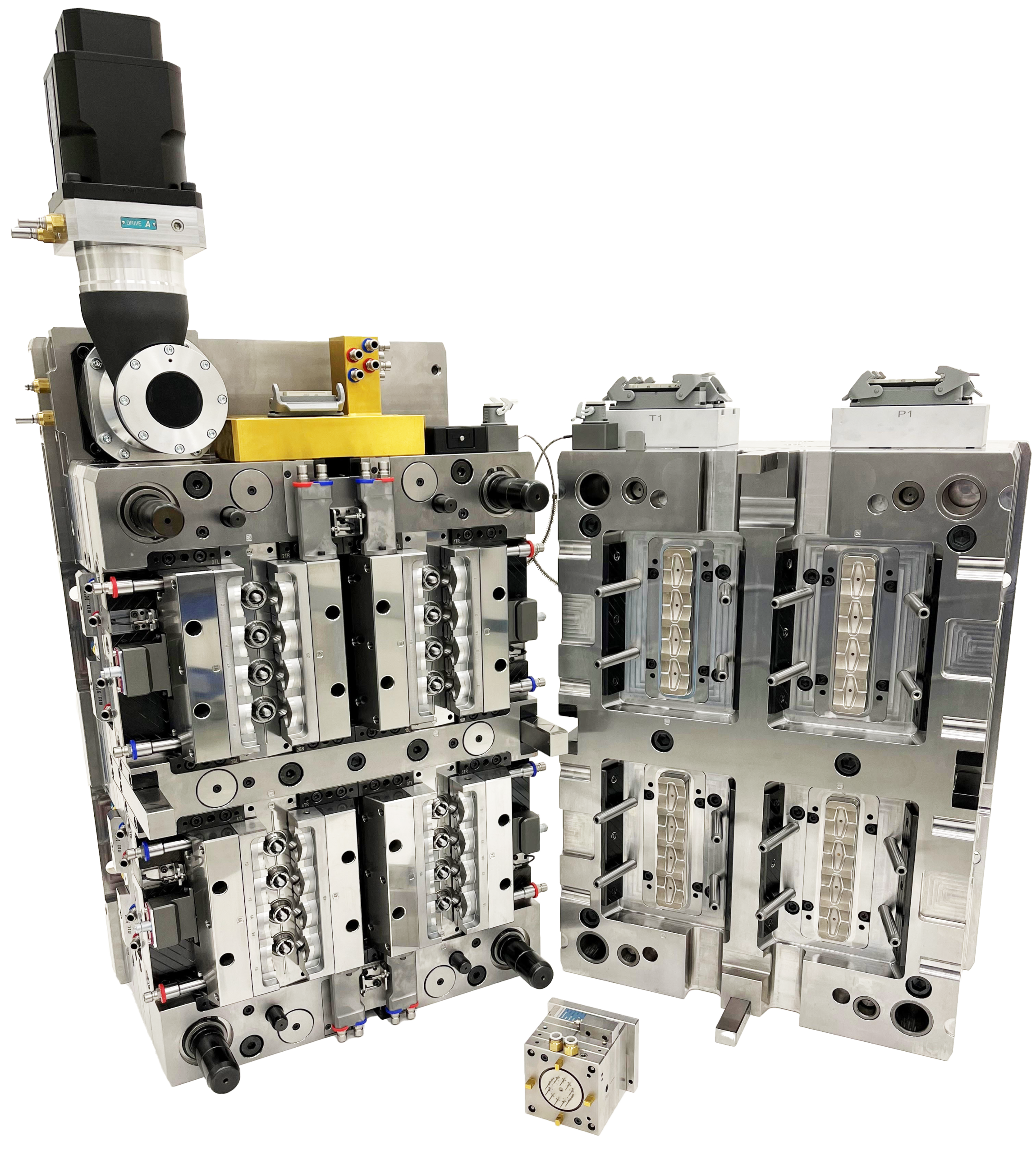

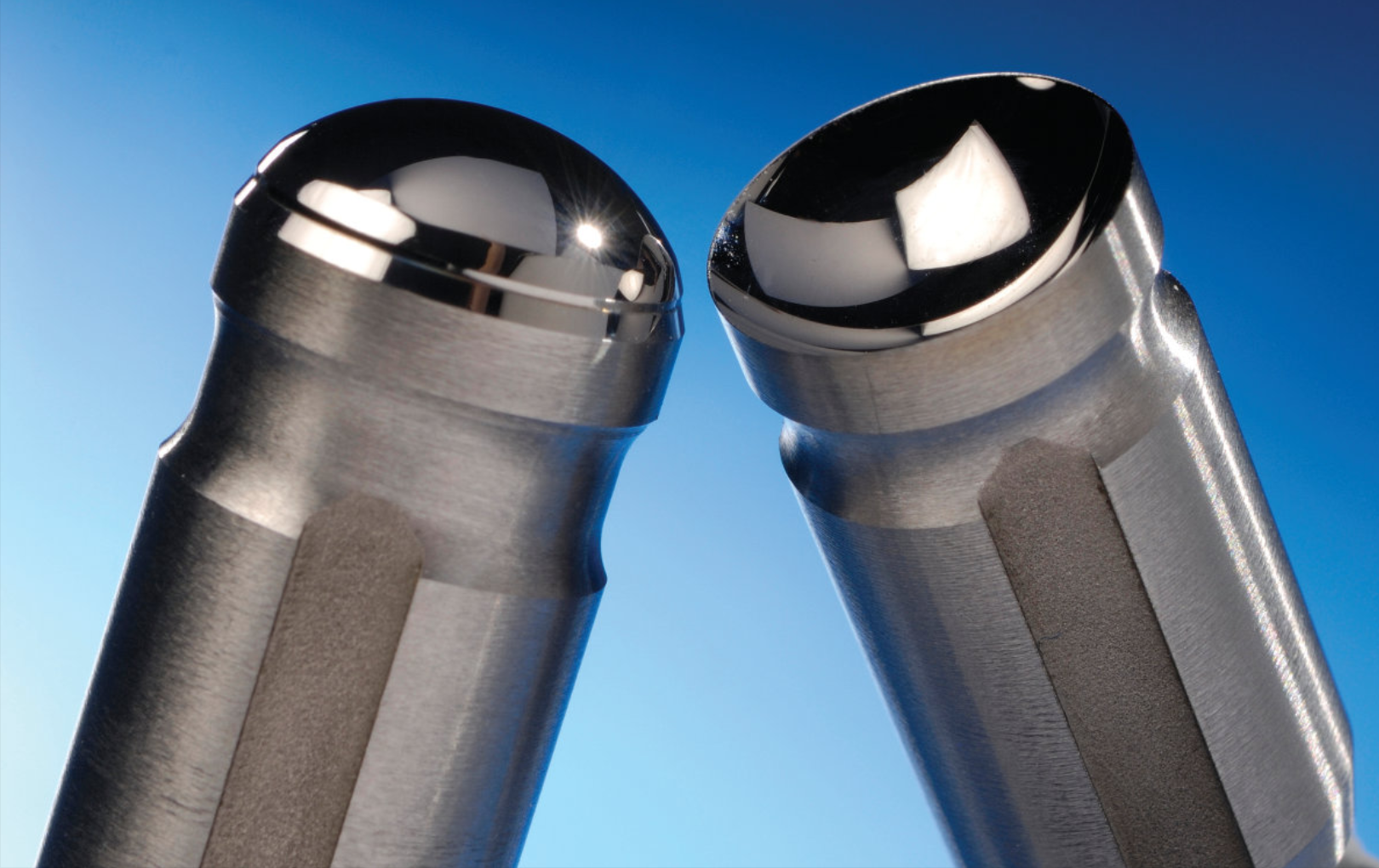

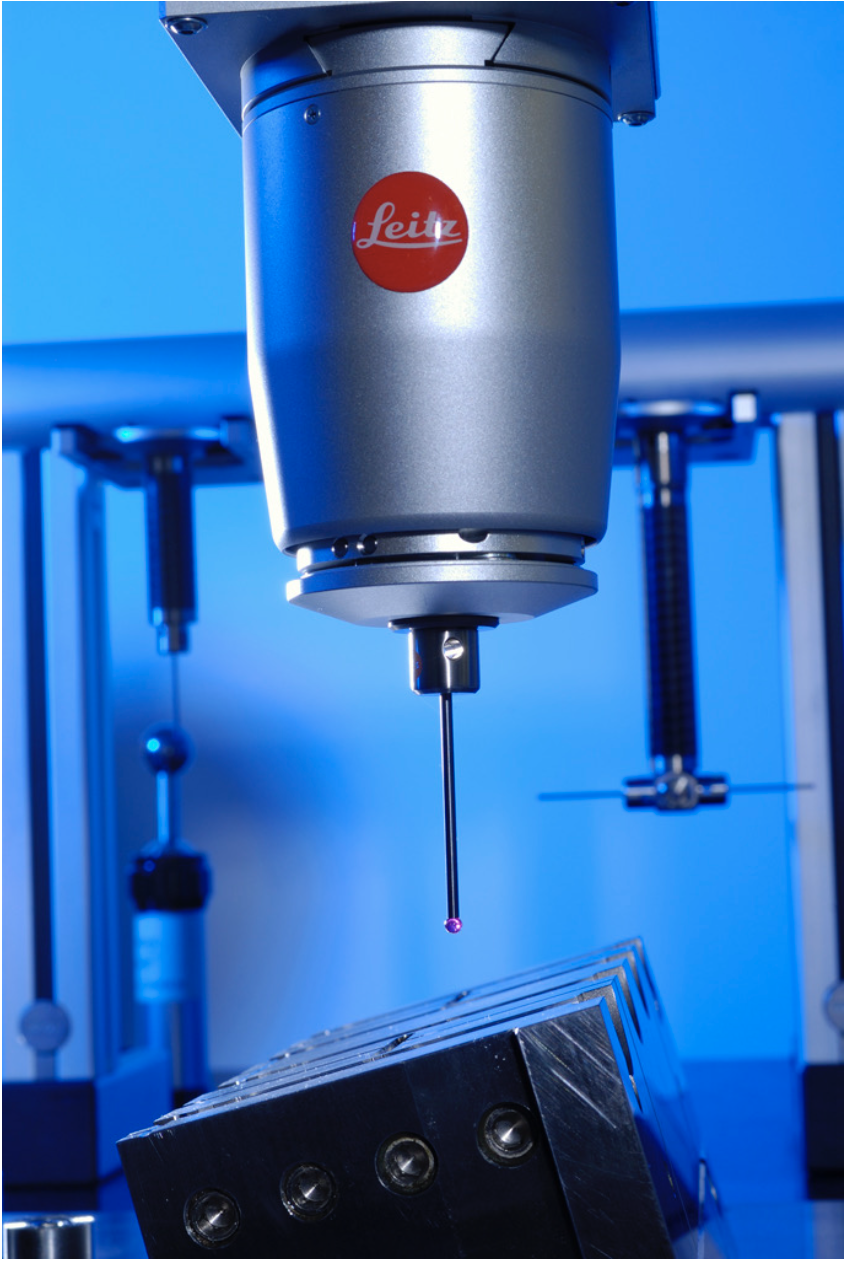

On-site Ultra-precision Mold Tooling

Comprehensive Mold Manufacturing and Injection Molding Services On-Site

- Injection Molding

- 2-Shot Molding

- Overmolding

- Validation

- Mold Testing & Evaluation

- Component Development

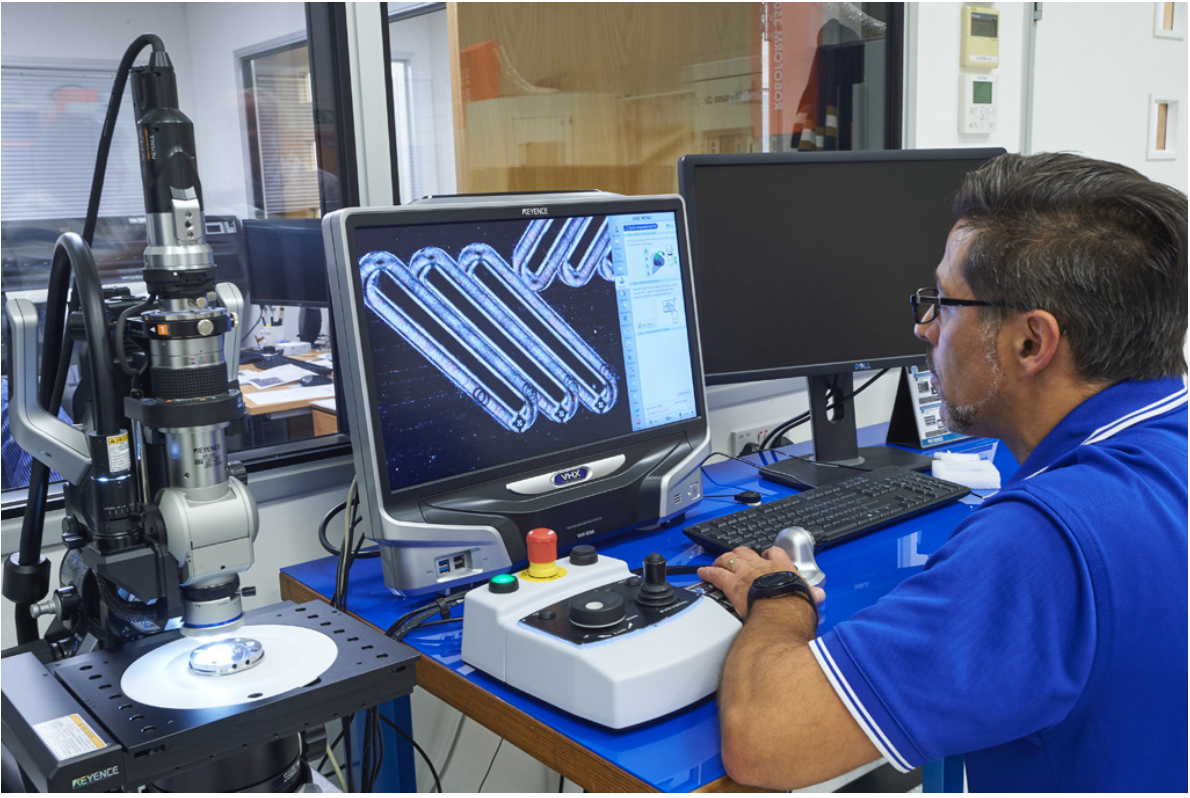

- Metrology

Customized Injection Molding for Complex Medical Applications

Thanks to our extensive expertise and advanced technology, Optimold rapidly delivers tailored molding solutions that meet the unique requirements of critical sectors. By working closely with our customers, we address complex technical challenges and consistently provide reliable, high-quality results that exceed expectations.

- Medical Devices

- Microfluidic Diagnostics

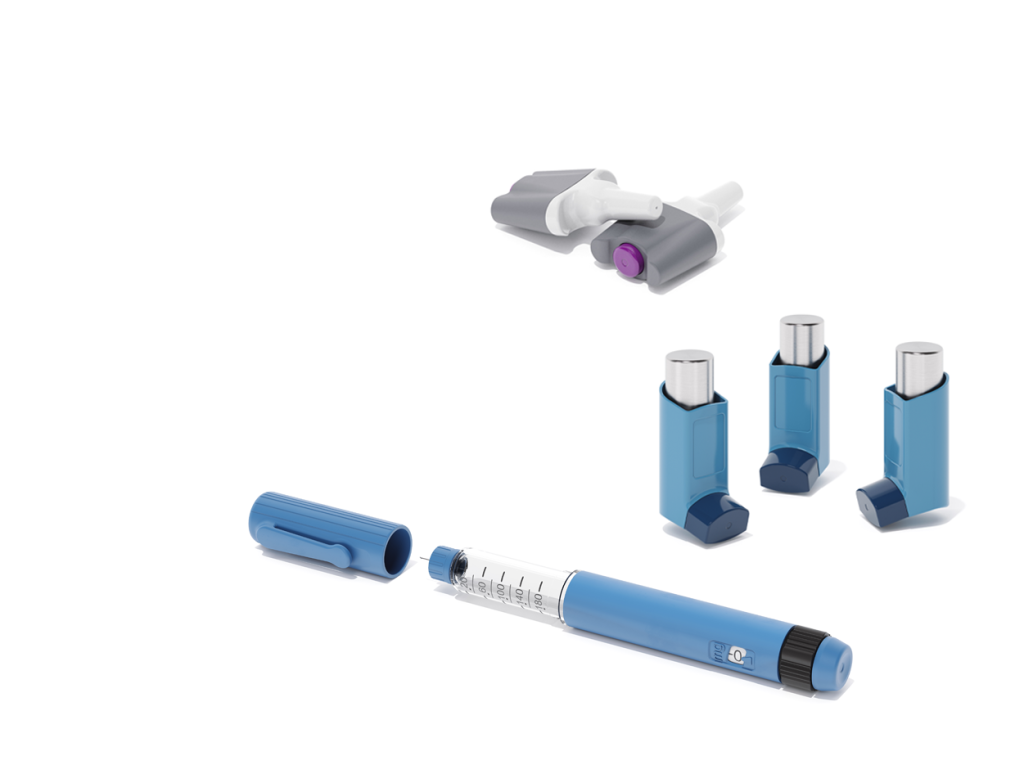

- Drug Delivery

- Ophthalmics

- Life Sciences and Biomedical

High-Precision Injection Molding with 24/7 Operation and Integrated Quality Control

- Fanuc 30T Injection Molding

- Husky Injection Molding

- Fanuc 300T Injection Molding

- 2-Shot Injection Molding

- Metrology facilities: CT Scanner, White-light interferometers, Vision systems, Digital Microscopes, CMM

News

Get the latest industry news and insights through our blog