Injection molding is a highly versatile and precise manufacturing process widely used in producing plastic components for drug delivery devices. These devices—including inhalers, auto-injectors, insulin pens, and nebulizers—require stringent quality, reliability, and biocompatibility standards to ensure safe and effective medication administration.

Why Injection Molding is Essential for Drug Delivery Devices

Drug delivery systems often demand complex geometries, multi-material components, and tight tolerances that traditional manufacturing methods struggle to achieve. The technology offers:

- High Precision and Consistency: Critical for dose accuracy and device reliability.

- Complex Multi-Material Molding: Supports overmolding and 2-shot molding for integrated seals, grips, and flexible components.

- Scalability: From prototypes to high-volume production with minimal cost variation.

- Material Versatility: Compatible with medical-grade polymers like polycarbonate, polypropylene, and cyclic olefin copolymers.

Key Considerations in Medical Molding for Drug Delivery

- Regulatory Compliance: Devices must meet ISO 13485 standards and FDA regulations, requiring validated processes and cleanroom molding environments.

- Biocompatibility: Use of FDA-approved, sterilizable polymers that are safe for patient contact.

- Precision Tooling: Ultra-precise molds are essential to achieve consistent part dimensions and functional integrity.

- Assembly and Integration: Injection molding often pairs with secondary operations like ultrasonic welding, insert molding, or component assembly to produce ready-to-use drug delivery devices.

Advances in Injection Molding for Drug Delivery

Innovations such as micro-injection molding enable the production of tiny, highly intricate parts used in microfluidic drug delivery and wearable injectors. Additionally, multi-shot molding techniques allow seamless integration of soft-touch grips or seals directly into rigid housings, reducing assembly steps and improving device durability.

Optimold’s Expertise in Drug Delivery Injection Molding

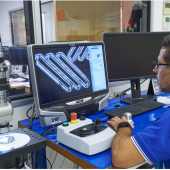

Optimold, together with Micro Systems, combines over 20 years of experience in medical injection molding with ISO 13485-certified processes and cleanroom facilities to manufacture critical components for drug delivery devices. Our turnkey solutions—from design-for-manufacturing (DfM) and mold tooling to validated production and assembly—ensure rapid development cycles and compliance with global regulatory demands. Supported by advanced metrology and comprehensive validation protocols, we deliver reliable, high-quality parts that enhance patient safety and device performance.

Injection molding is a foundational technology in the manufacture of modern drug delivery devices, offering precision, material versatility, and scalable production while meeting stringent medical standards. Partnering with experienced contract manufacturers like Optimold ensures that your drug delivery systems are produced with the quality and reliability required for today’s healthcare market.

Contact us today!