High-performance materials for medical injection molding

Optimold, an ISO 13485-certified manufacturer, specializes in precision injection molding of advanced thermoplastics and ultra-engineered materials for critical medical applications. Our expertise in material performance and process control ensures compliance with stringent mechanical, thermal, and biocompatibility requirements. From design through production, we deliver high-reliability components that meet the most demanding standards of the medical industry.

Our range of materials include: PEEK, ABS, HDPE, LCP, LDPE, PS, PC, PBT,… and others on request.

-

PEEK

A high-performance, semi-crystalline thermoplastic known for its exceptional mechanical strength, chemical resistance, and thermal stability. Its biocompatibility and ability to withstand repeated autoclave sterilization make it ideal for precision-molded medical implants and devices. -

ABS

An amorphous thermoplastic with good impact strength and dimensional stability, ideal for non-implantable medical housings. We also mold a range of ABS blends for specific performance and regulatory requirements. -

HDPE

A semi-crystalline polyolefin known for its high impact strength, chemical resistance, and low moisture absorption, widely used in injection-molded disposable medical components and fluid handling systems. -

LCP

A high-performance thermoplastic with exceptional strength, thermal stability, and chemical resistance. It is ideal for precision medical components requiring high dimensional stability and reliability in demanding environments. -

LDPE

A flexible, semi-crystalline polyolefin with excellent chemical resistance and impact strength. Its softness and ease of molding make it ideal for medical components like caps, connectors, and disposable parts. -

LLDPE

A tough, flexible polyolefin with excellent impact resistance, chemical resistance, and stress crack resistance. It is well-suited for injection-molded medical components such as seals, caps, and flexible housings. -

LLDPE

A tough, flexible polyolefin with excellent impact resistance, chemical resistance, and stress crack resistance. It is well-suited for injection-molded medical components such as seals, caps, and flexible housings. -

Polypropylene (PP)

A lightweight, flexible thermoplastic with excellent chemical resistance, low moisture absorption, and good fatigue resistance, commonly used in injection-molded medical components such as containers, closures, and disposable parts, where durability and sterility are key. -

PPE/PS

A thermoplastic blend that combines the strength and impact resistance of PPE with the clarity and processability of PS. It is ideal for injection-molded medical components such as diagnostic housings, medical device enclosures, and transparent covers, offering both durability and optical clarity. -

SB (Styrene-Butadiene)

A flexible, impact-resistant thermoplastic with excellent processability and good low-temperature performance, commonly used in injection-molded medical components such as gaskets, seals, and flexible tubing, offering durability and resilience in demanding applications. -

SB (Styrene-Butadiene)

A flexible, impact-resistant thermoplastic with excellent processability and good low-temperature performance, commonly used in injection-molded medical components such as gaskets, seals, and flexible tubing, offering durability and resilience in demanding applications.

-

PC/PBT

A thermoplastic blend that combines the toughness and impact resistance of polycarbonate with the chemical resistance and dimensional stability of PBT. It is ideal for injection-molded medical housings and components requiring durability in chemically demanding environments. -

Nylon (PA)

A strong, semi-crystalline thermoplastic with excellent wear resistance, toughness, and chemical resistance, commonly used in injection-molded medical components requiring durability, such as surgical instrument handles and connectors. -

PBT

A semi-crystalline polyester with excellent dimensional stability, chemical resistance, and electrical insulating properties, ideal for injection-molded medical components such as connectors, housings, and diagnostic device parts. -

Polycarbonate (PC)

A tough, transparent thermoplastic with high impact resistance, dimensional stability, and good thermal properties, widely used in injection-molded medical components and surgical device parts requiring clarity and durability. -

PEI (Ultem)

A high-performance, amorphous thermoplastic with excellent mechanical strength, thermal stability, and inherent flame resistance, ideal for injection-molded medical devices, surgical instruments, and diagnostic components. -

PMMA (Acrylic)

A rigid, transparent thermoplastic with excellent optical clarity, UV resistance, and dimensional stability, commonly used in injection-molded medical components and display covers where clarity and aesthetics are essential. -

POM (Acetal/Delrin)

A high-stiffness, low-friction, semi-crystalline thermoplastic with excellent dimensional stability and chemical resistance, ideal for injection-molded medical components and surgical instrument parts requiring durability and wear resistance. -

PS

A versatile, rigid thermoplastic known for its ease of processing, excellent clarity, and dimensional stability, commonly used in injection-molded medical components and diagnostic device housings, where transparency and cost-effectiveness are important. -

TPU (Thermoplastic Polyurethane)

A versatile, flexible thermoplastic with excellent abrasion, chemical, and impact resistance, commonly used in injection-molded medical components such as catheters, seals, and tubing, offering durability and flexibility in demanding applications. -

TP/TPV

A highly durable, flexible thermoplastic elastomer with excellent heat, chemical, and abrasion resistance, ideal for injection-molded medical components such as seals and flexible connectors, offering flexibility and long-lasting performance in demanding environments. -

Others

We also work with other custom high-performance materials tailored to meet specific medical application requirements. Our experts and advanced technology fully support customers in processing the ideal material to meet their exact needs and regulatory standards.

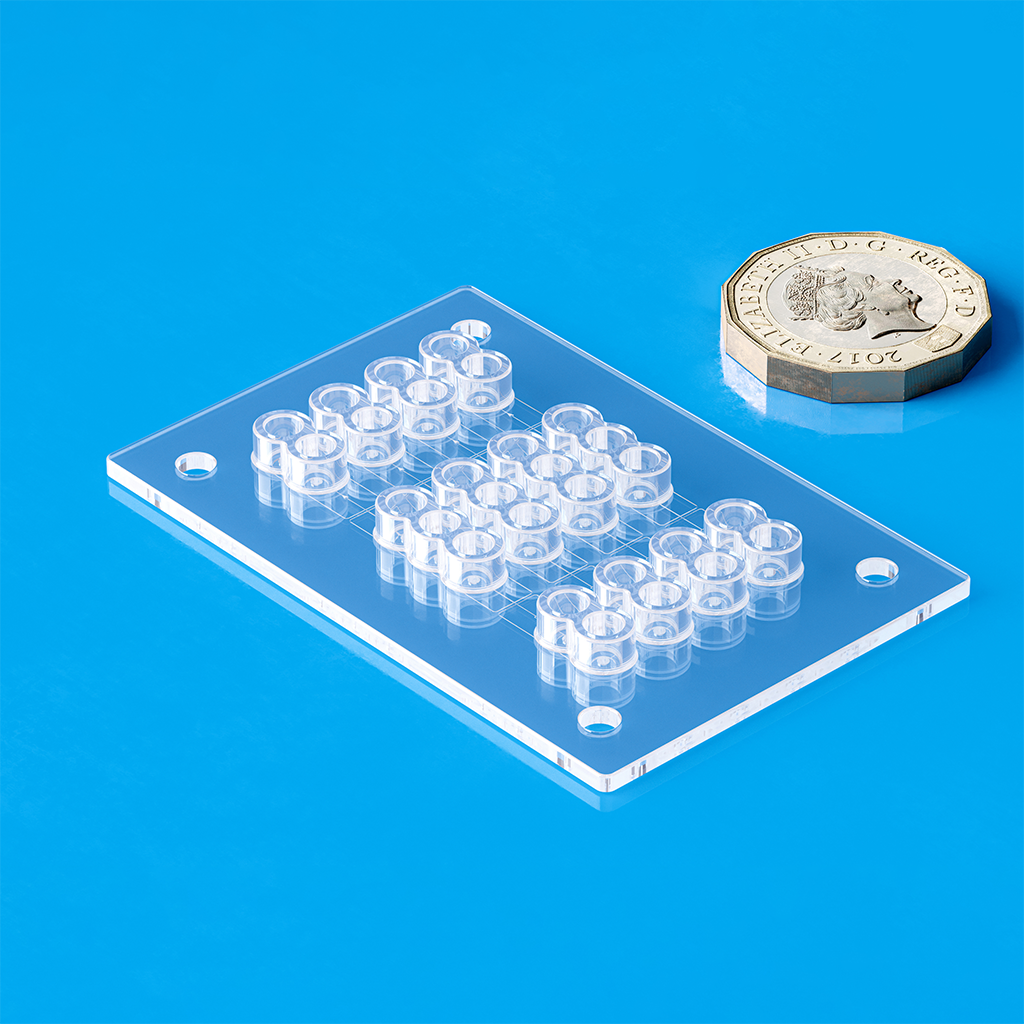

Examples of precision medical components engineered with high-performance materials using advanced injection molding at Optimold

Get in touch with our Injection Molding experts

With over 20 years of experience, we bring the expertise and innovation to engineer and manufacture custom solutions using high-performance materials for your advanced medical components and devices.