Manufacturing Excellence for Comprehensive Life Science and Biomedical Plastic Solutions

Optimold delivers ISO 13485-certified manufacturing excellence for Life Science and Biomedical plastic components. With over a decade of experience in medical-grade injection molding, we support the full product lifecycle—from mold design to validated mass production. Our precision-engineered solutions meet stringent regulatory and performance requirements, helping customers optimize device functionality and manufacturing efficiency. Backed by in-house tooling and robust engineering expertise, Optimold enables scalable, compliant production for critical biomedical applications.

Extensive Solutions for Life Science and Biomedical Applications

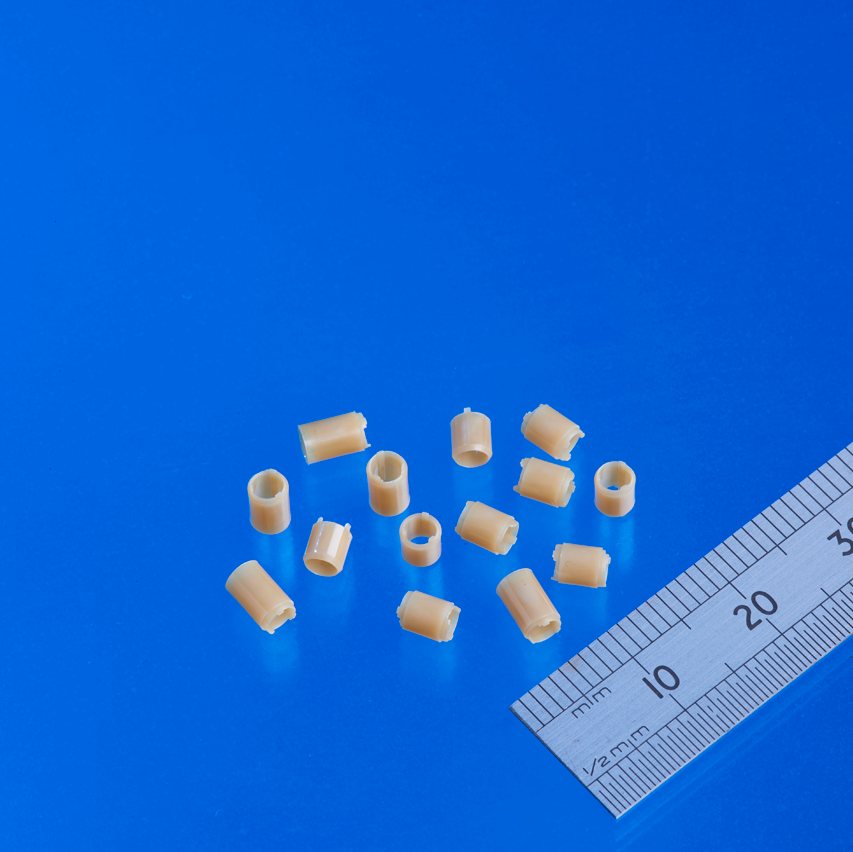

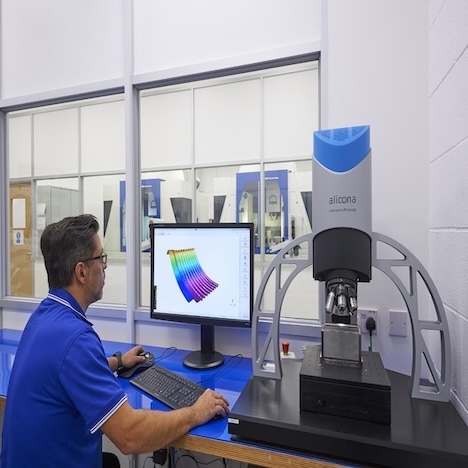

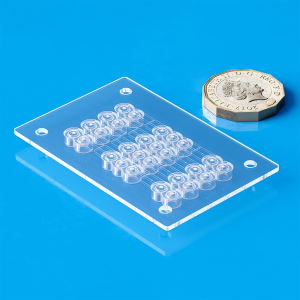

Our expertise in injection molding thin-wall, tight-tolerance, and geometrically complex components using chemically inert materials like ABS and PEEK uniquely positions us to serve a broad range of life science and biomedical applications. We operate within Class 7 and Class 8 cleanroom environments to ensure the highest levels of contamination control. Additionally, we leverage advanced robotic handling and vision inspection systems to maintain exacting quality standards—achieving precision and consistency beyond the capabilities of traditional inspection methods. This combination of materials expertise, cleanroom manufacturing, and cutting-edge quality control ensures our components meet the rigorous demands of the biomedical industry.

Life Science and Biomedical Molding examples

PEEK bone implants of…

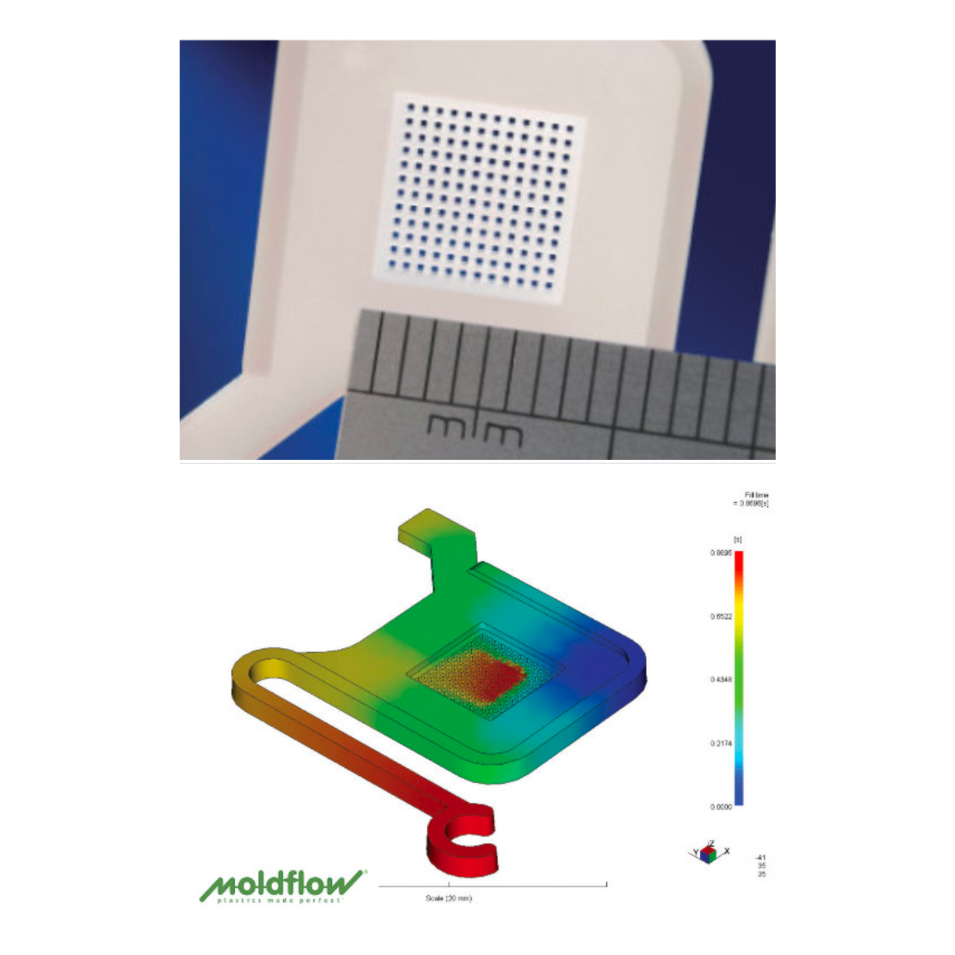

Conformal cooling of…

Turnkey Development and Mass Production of Life Science and Biomedical Plastic solutions

At Optimold, we deliver medical-grade components with exceptional quality and performance—whether it’s a full device or a single part. Our end-to-end process streamlines development and speeds time to market, supporting everything from rapid launches to long-term programs. On-site partner Micro Systems, with 20+ years of expertise and ISO 13485 – 9001 certifications, provides ultra-precision mold design and tooling. Together, we offer seamless collaboration, scientific molding, and advanced manufacturing to meet the most demanding life science standards.

Beyond Life Science and Biomedical Injection Molding

Optimold provides industry-leading customer service and support for your Life Science and Biomedical Molding projects, including:

- Precision Injection Molding: high-precision molding, 2K-molding, …

- A range of high-performance engineered materials: PEEK, ABS,…

- Scalable solutions: from small lot to multi-million unit batches

- In-house tooling: ultra-precision mold (single and multi-cavity, micro mold)

- Quality Management: Validation services: FAT to full IQ, OQ, PQ – Mold testing and evaluation

- Extensive Metrology capabilities

Explore other applications

Talk to us about your Life Science and Biomedical Molding project

Ready to accelerate your Life Science and Biomedical applications production with precision and efficiency? Partner with Optimold for ISO 13485-certified, cleanroom injection molding and integrated tooling solutions.