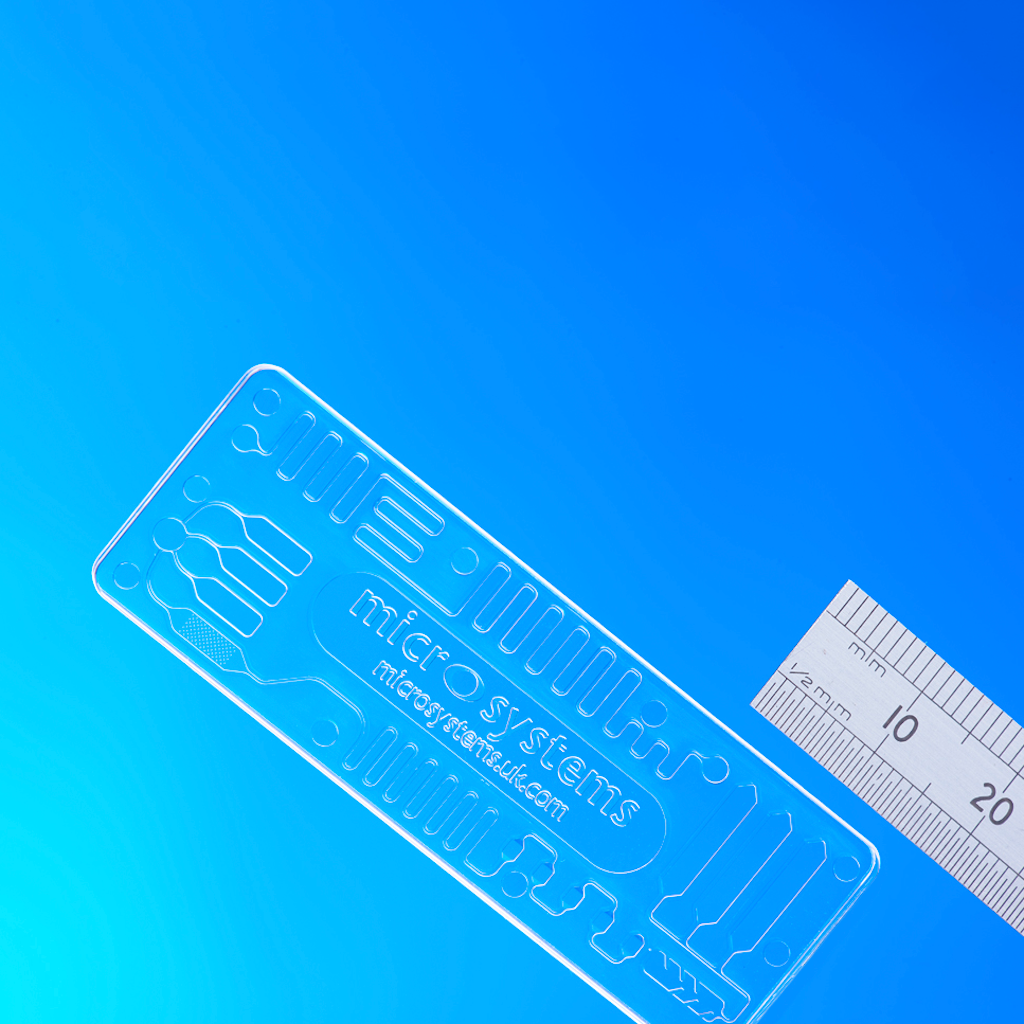

Comprehensive turnkey injection molding solutions

Optimold offers comprehensive turnkey injection molding solutions, supporting the full product lifecycle—from initial mold design and validation to high-quality mass production. With over 10 years of experience and ISO 13485 certification, together with our sister company Micro Systems, we provide flexible, end-to-end contract development and manufacturing services tailored to the needs of various markets. Whether engaging at design stage or mid-development, our expert team, advanced tools, and commitment to quality excellence ensure your product is delivered efficiently, cost-effectively, and to the highest standards.

Synergy to streamline the entire development and validation process

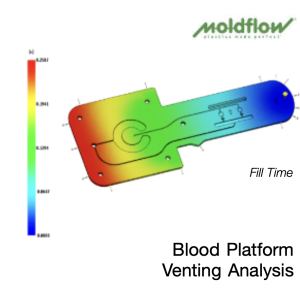

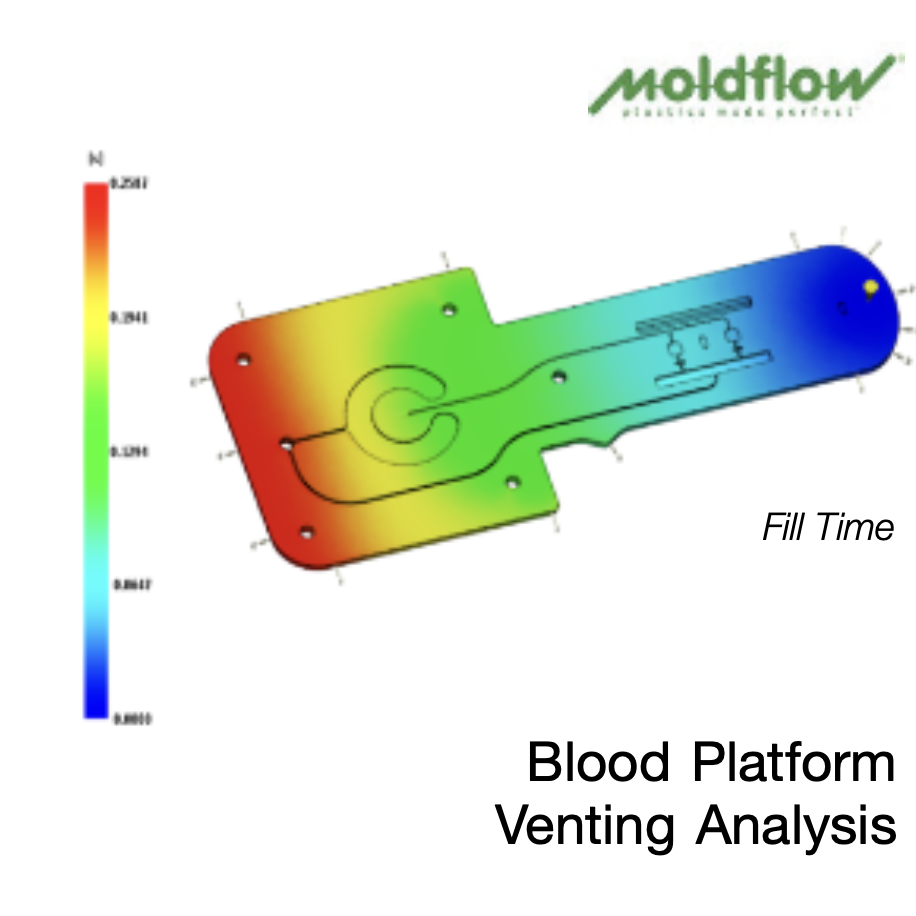

DFMEA

DFMEA-driven design and commercialization of high-volume molded medical device components using Siemens NX, Moldflow, and Fusion 3D FEA

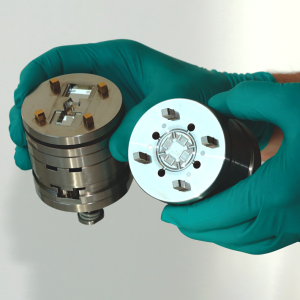

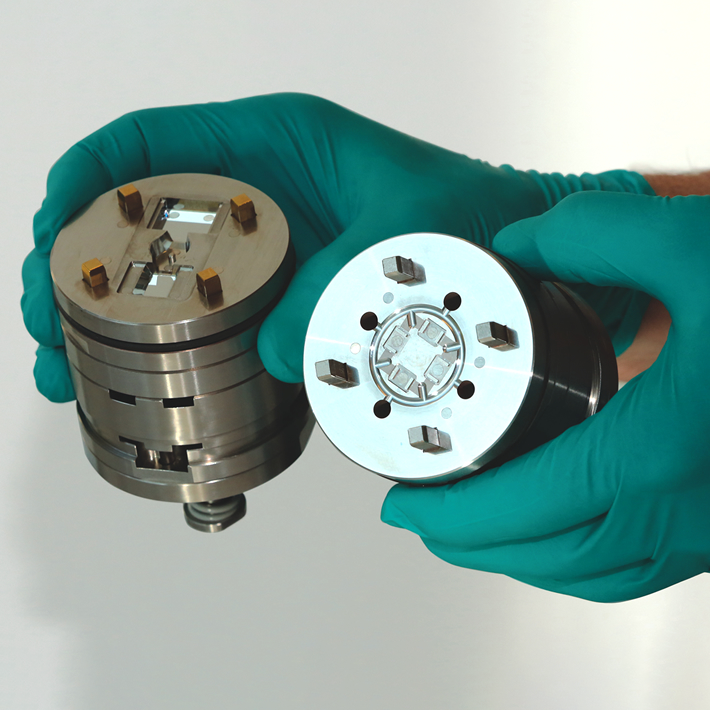

Mold Manufacture

World-class tool room with sub-micron accuracy equipment, supported by our Singapore facility for increased capacity and faster delivery

Mold Testing & Development

Advanced mold testing facility with expert engineers using Pro-Op, Minitab, and Cap Studies to ensure robust processes and maximum capability

Validation

Complete validation of mold tools and molding process through IQ, OQ and PQ phases complying to ISO13485 accreditation

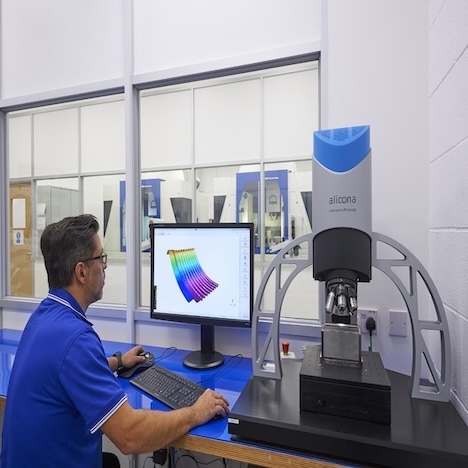

Metrology

Metrology

In-house metrology lab with advanced CMM, scanning, and CT tools, supported by GOM software for efficient, comprehensive reporting

Production Molding

Production Molding

ISO13485-certified molding facility with 20 machines from 15T to 300T, including multiple 160T twin-shot units

Explore our services

Explore our services

Injection Molding

ISO 13485 accredited molding facility with 20 IMMs from 15T to 300T including multiple 160T 2-shot IMMs

Learn more

2-Shot Molding

Small batch to mass production using the latest technology in 2-shot molding in cleanroom facilities

Learn more

Overmolding

Enhance durability and performance for a range of aplications with precision over molding

Learn more

Validation

Complete validation of mold tools and molding process through IQ, OQ and PQ complying to ISO 13485

Learn more

Mold Testing & Evaluation

Comprehensive mold development using Pro-Op, Minitab, and Cap Studies for maximum capability

Learn more

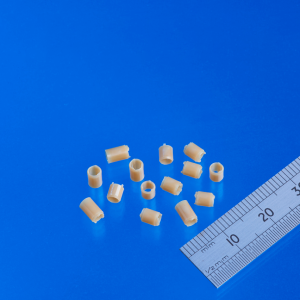

Component Development

End-to-end process involves optimizing molding parameters to ensure parts meet quality, consistency, and cost targets.

Learn more

Metrology

Extensive in-house metrology lab including CT Scanning with GOM licenses to efficiently generate complete metrology reports

Learn more

Other custom services

A range of advanced injection molding supporting services customized to each project, industry and special requirements

Contact us

Get in touch with our experts

From Mold Design to mass production of injection molded components, we are your trusted molding partner—start your project today!