ISO 13485 Ultra-Precision Injection Molding

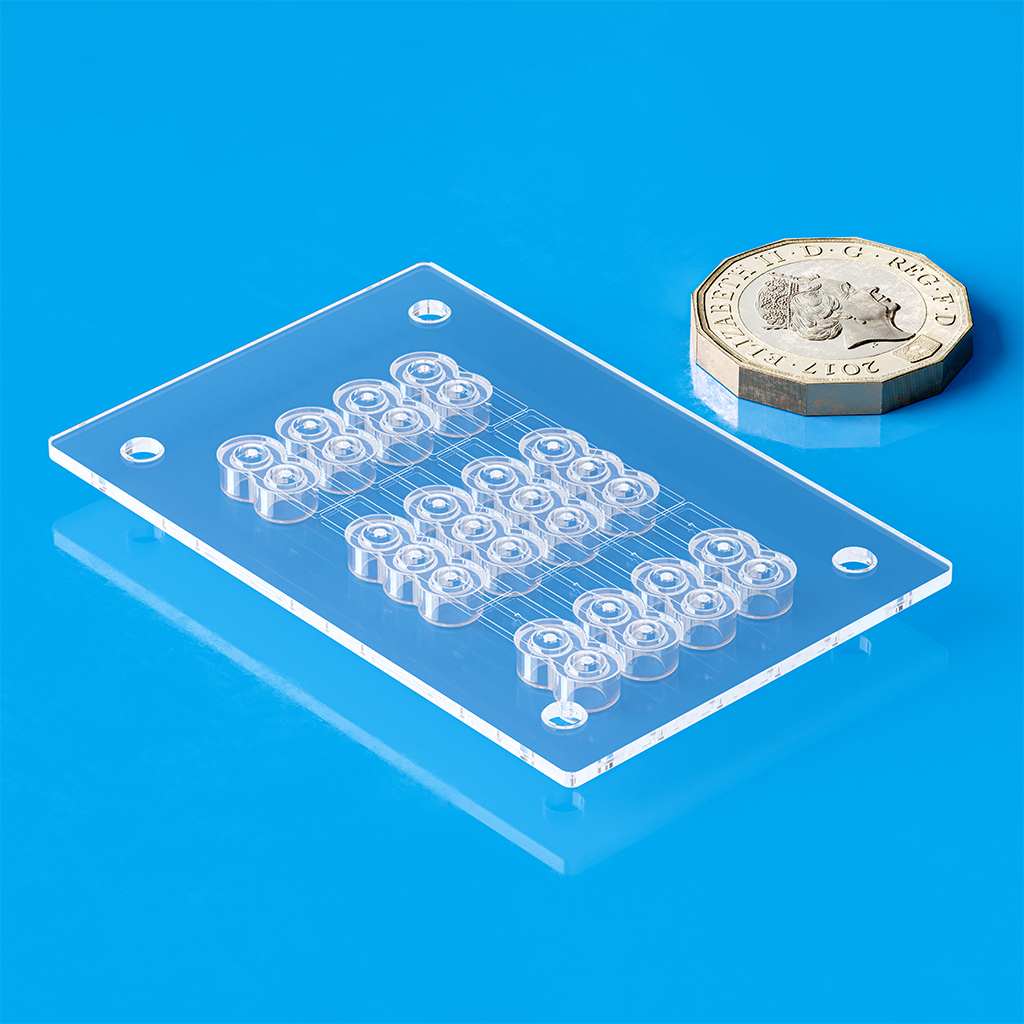

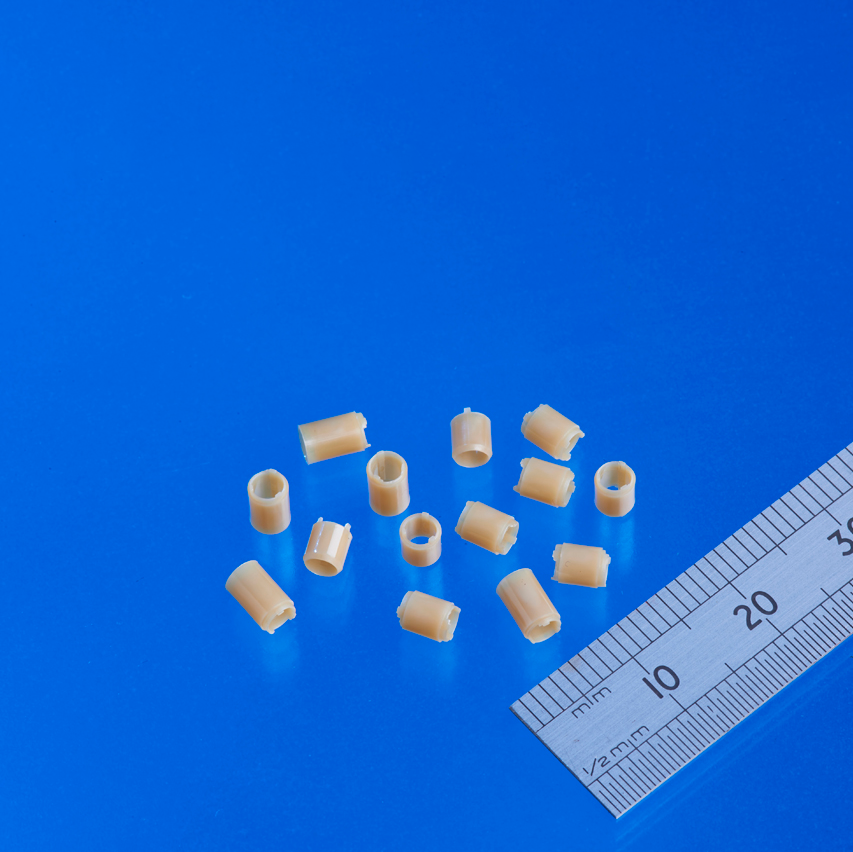

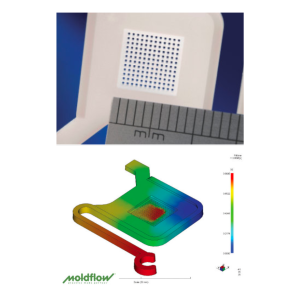

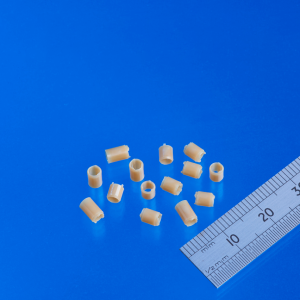

Optimold specializes in high-precision injection molding, delivering complex, tight-tolerance components from microstructures to high volumes with ISO 13485-certified quality. Using world-class Micro Systems tooling and validated processes, we ensure reliable, medical-grade production at scale.

Capillary clamps

Injection pen

Lens packaging

Why choose us?

16 injection molding machines from 30t to 300t

24/5 and 24/7 production capability

On-site mold making and micro molding facilities at Micro Systems

Component weights between….. Wall thickness between…. Accuracy between…

Class 7 Cleanroom Injection Molding facilities. ISO:13485 accredited facility

Hydraulic and all-electric molding machinery. Robotic handling and packing facilities

High-performance medical grade materials including PEEK, COP,…

Validation services – FAT to full IQ, OQ, PQ. Mould testing and evaluation capability. Extensive Metrology facilities

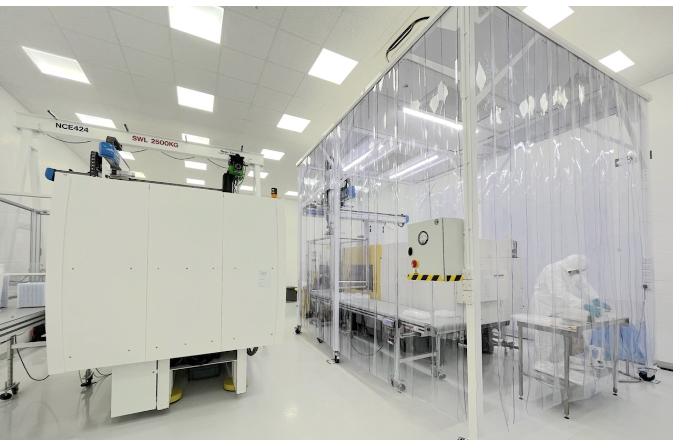

Cleanroom Injection Molding

We are a full-service medical device manufacturing company offering advanced plastic injection molding services within Class 7 cleanroom facilities. Our cleanroom environment ensures the highest levels of hygiene and contamination control, making it ideal for producing critical medical components with precision and consistency.

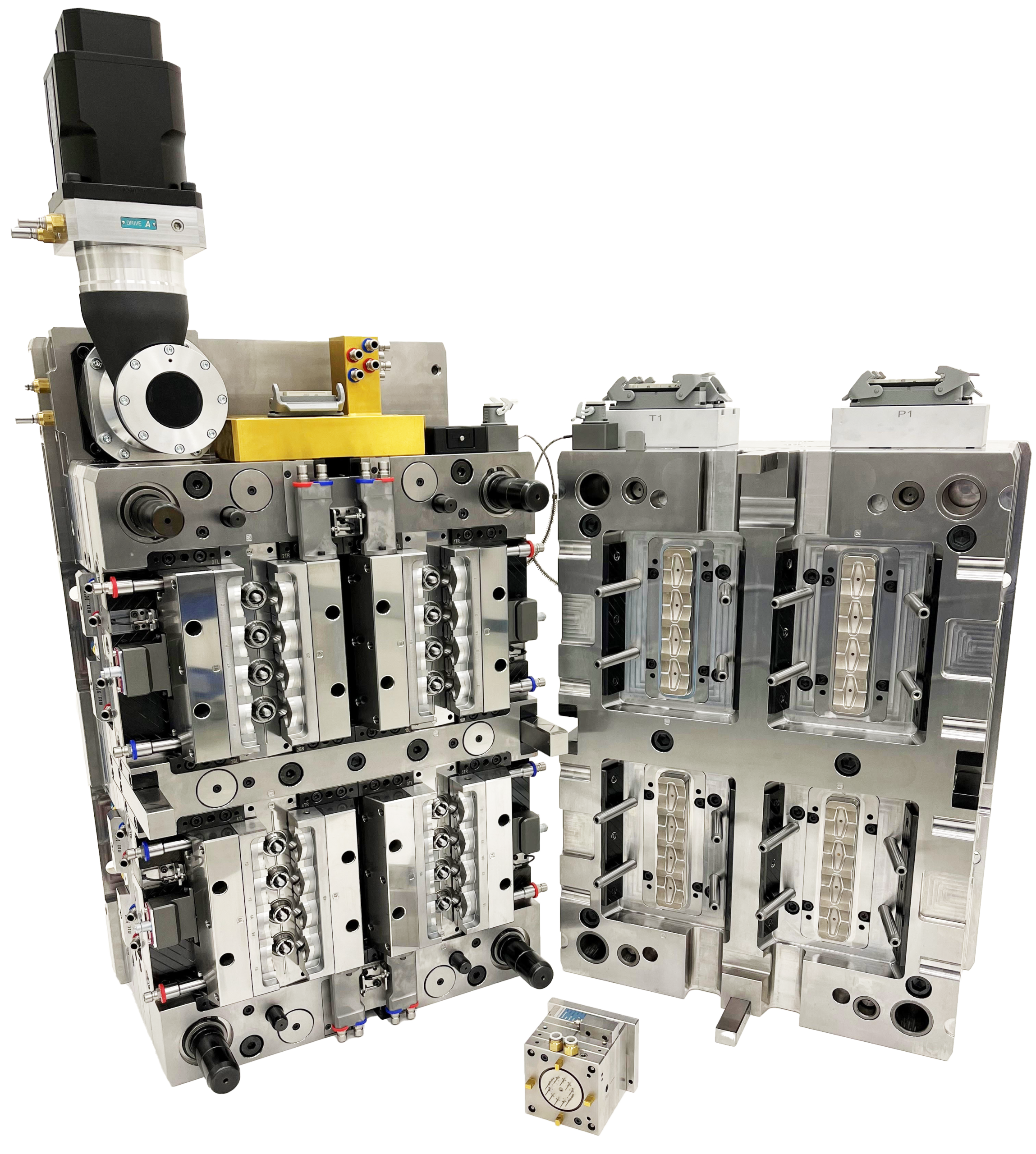

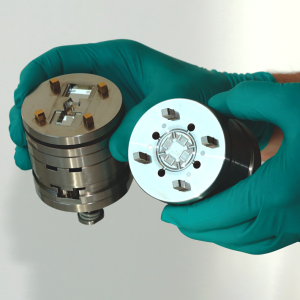

In-house ultra-precision mold tooling

At Optimold, our in-house tooling—co-located with Micro Systems for moldmaking and micro-molding—ensures seamless collaboration between engineers and designers. This close integration allows us to respond quickly to real-world molding conditions that may differ from initial designs, enabling rapid adjustments and optimization. With everything on-site, we deliver faster tool development, improved accuracy, and immediate production support, ensuring the highest quality and performance at every stage.

Molding excellent for various applications

With over 10 years of experience, we specialize in markets and applications that demand the highest standards of precision, quality, and performance. Our dedicated quality management system, backed by certifications like ISO 13485, is built to meet the strict requirements of these industries.

Synergy to streamline the entire Development and Validation process

At Optimold and Micro Systems, we deliver complete end-to-end manufacturing solutions that go far beyond standard injection molding services. True success—especially at scale—relies on getting the entire process right from the start. Our projects begin with Design for Manufacturability (DfM) guided by DFMEA, followed by pilot runs using 2-cavity molds to validate design, prove functionality, and catch issues early—reducing risk and cost. Only then do we scale to full production tooling, typically 8, 16, or 32 cavities, enabling efficient, high-volume manufacturing with consistent quality and compliance. This integrated approach ensures your project is built for long-term success.

- DFMEA

- Mold Manufacture

- Mold Testing & Development

- Validation

- Metrology

- Production Molding

Explore other services

Talk to us about your Injection Molding requirements

Ready to bring your product to life? Contact us today for expert injection molding solutions, cleanroom manufacturing, and ISO 13485-certified quality.