ISO 13485 2-Shot Injection Molding

Optimold bring over 10 years of industry experience and expert mold design capabilities to deliver precision 2-Shot injection molding solutions, supporting the creation of complex, multi-material parts with enhanced functionality and design flexibility.

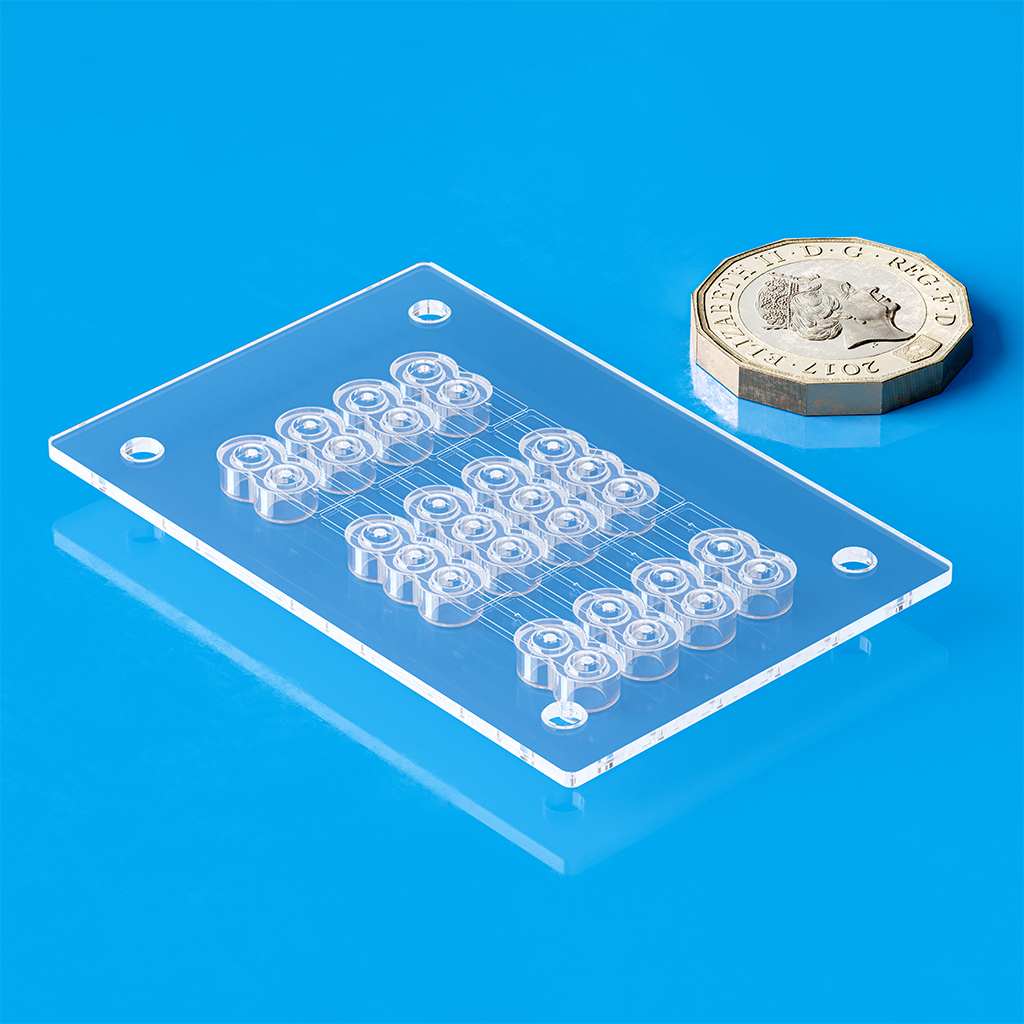

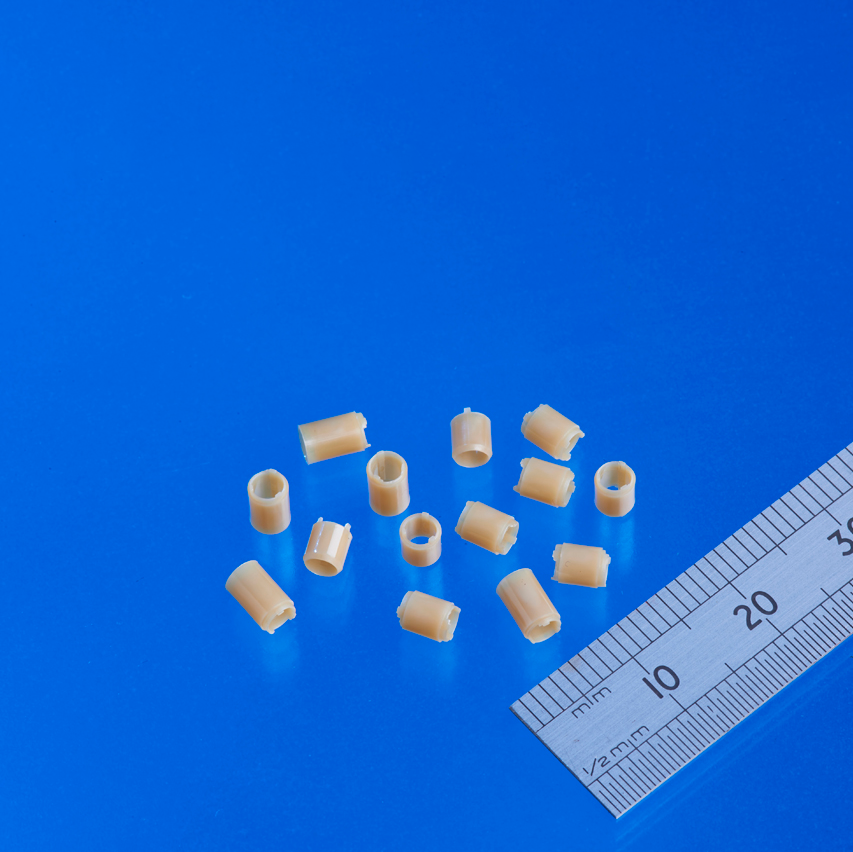

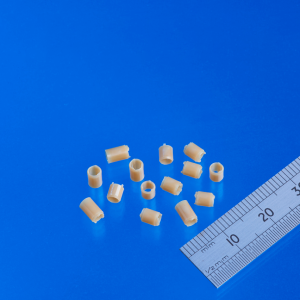

Capillary clamps

Injection pen

Lens packaging

Why choose us?

3 2-Shot Krauss Maffei molding machines. Access to 6 MicroPower 15 Micro Molding machines with in-line 2-shot capabilities

24/5 and 24/7 production capability

On-site mold making and micro molding facilities at Micro Systems

Component weights between….. Wall thickness between…. Accuracy between…

High-performance medical grade materials including PEEK, COP,…

Class 7 Cleanroom Injection Molding facilities. ISO:13485 accredited facility

Benefits of 2-Shot Molding

2-Shot Molding (or 2K Molding) is a process that injects 2 materials simultaneously in a single cycle, allowing for multi-component parts with complex shapes and structures. While technically demanding, it offers key advantages such as high product quality, consistency, productivity, and exceptional design flexibility.

- Higher repeatability and accuracy – Less costs and cycle times

- Improved bonding and quality, tighter tolerances

- More complex aesthetics and haptics (multi-color, multi-material components)

Extensive 2-Shot Molding capabilities

At Optimold, decades of hands-on experience and deep technical expertise in 2-shot molding set us apart. With on-site mold tooling capabilities and a collaborative, solutions-driven approach, we guide our customers through every stage of development, from Mold Design to finished product. Our highly trained engineers offer tailored advice on bonding methods—chemical, mechanical, or catalyst-assisted—to ensure optimal performance. The result: high-quality, precision-molded components that meet stringent requirements at competitive prices.

Advanced 2-Shot Molding facilities

Our 2-Shot Injection Molding workshop is equipped with 3 advanced 2-shot Krauss Maffei machines, delivering high-efficiency, low-cost production ideal for rapid mass manufacturing. Located within a certified ISO Class 7 and class 8 cleanrooms when required, our facility ensures strict contamination control—making it perfectly suited for medical device components. This dual-material molding process enhances product functionality while reducing assembly time and cost, all within a controlled, compliant environment.

At our on-site sister company Micro Systems, there are 6 MicroPower 15 Micro Moulding machines with in-line 2-shot capabilities to meet custom requirements.

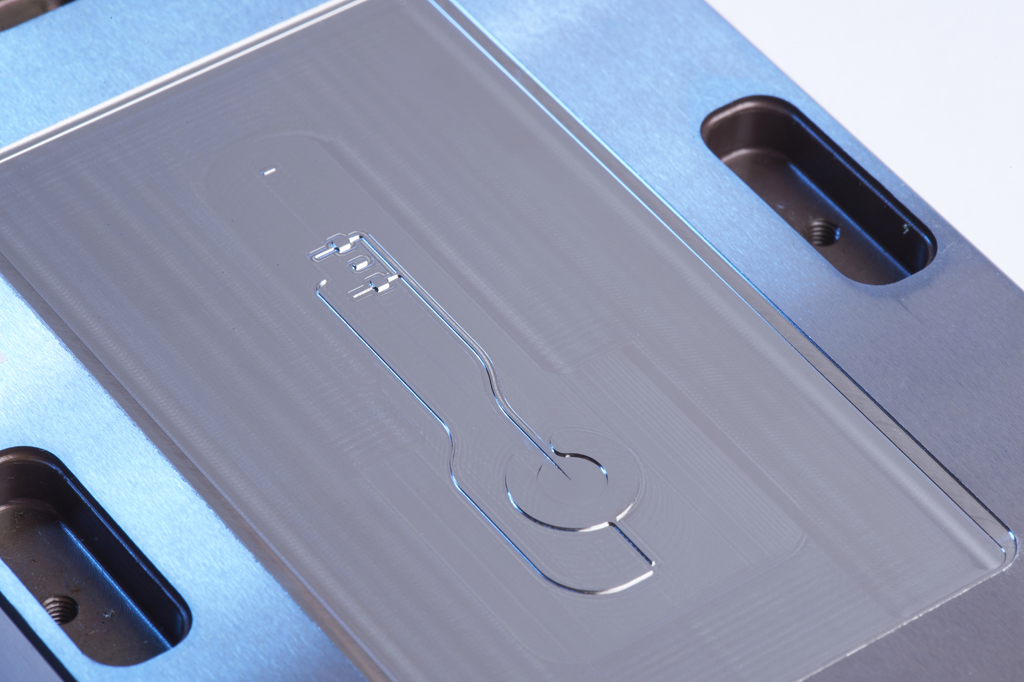

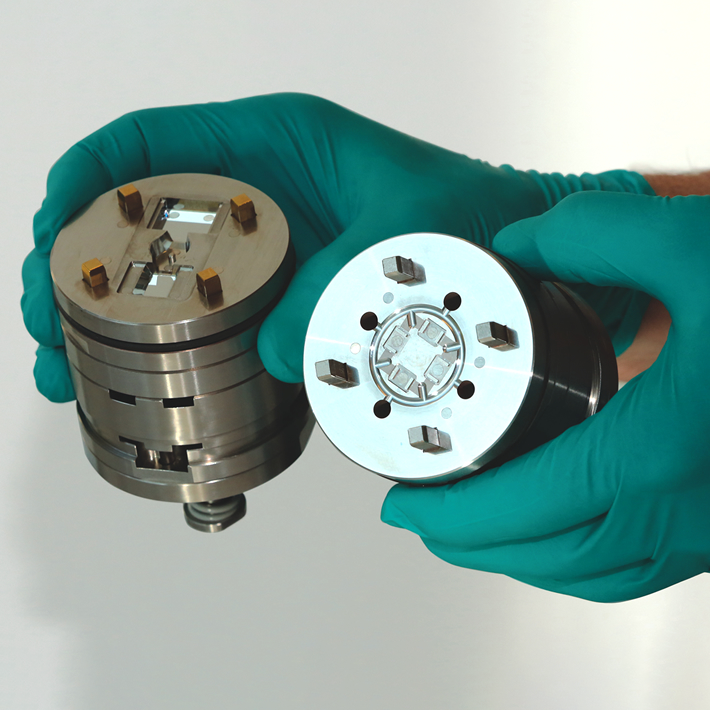

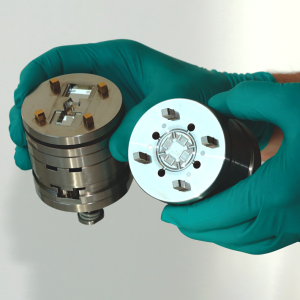

In-house ultra-precision 2-Shot mold tooling

Having on-site mold tooling and expert engineers is vital for successful 2K injection molding. At Optimold, we partner with Micro Systems—an ISO 9001 and 13485-certified ultra-precision mold maker—to ensure every mold is crafted with exacting standards. This close collaboration enables precise design, material selection, and rapid mold adjustments, guaranteeing high-quality, durable components that meet strict medical industry requirements.

Molding excellent for various applications

Optimold delivers high-quality 2K injection molded parts engineered compliant with ISO 13485 standards. Our components provide enhanced performance, cost efficiency, and durability, supporting critical applications with precision and reliability to ensure product safety and device longevity.

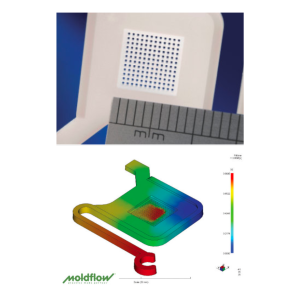

Synergy to streamline the entire Development and Validation process

At Optimold and Micro Systems, we deliver complete end-to-end manufacturing solutions that go far beyond standard injection molding services. True success—especially at scale—relies on getting the entire process right from the start. Our projects begin with Design for Manufacturability (DfM) guided by DFMEA, followed by pilot runs using 2-cavity molds to validate design, prove functionality, and catch issues early—reducing risk and cost. Only then do we scale to full production tooling, typically 8, 16, or 32 cavities, enabling efficient, high-volume manufacturing with consistent quality and compliance. This integrated approach ensures your project is built for long-term success.

- DFMEA

- Mold Manufacture

- Mold Testing & Development

- Validation

- Metrology

- Production Molding

Explore other services

Talk to us about your 2-Shot Molding requirements

Achieve precision, durability, and compliance — partner with us for ISO 13485-certified 2-Shot Molding solutions that advance medical innovation