Overmolding services for complex applications

Optimold provides ISO 13485-certified overmolding services, offering expert support from mold design through to mass production. With in-house mold tooling and deep technical knowledge, we deliver excellent overmolding solutions tailored to your needs. As a leading supplier of overmolding service and ultra-precision mold tooling, we help you achieve your project goals with precision and confidence.

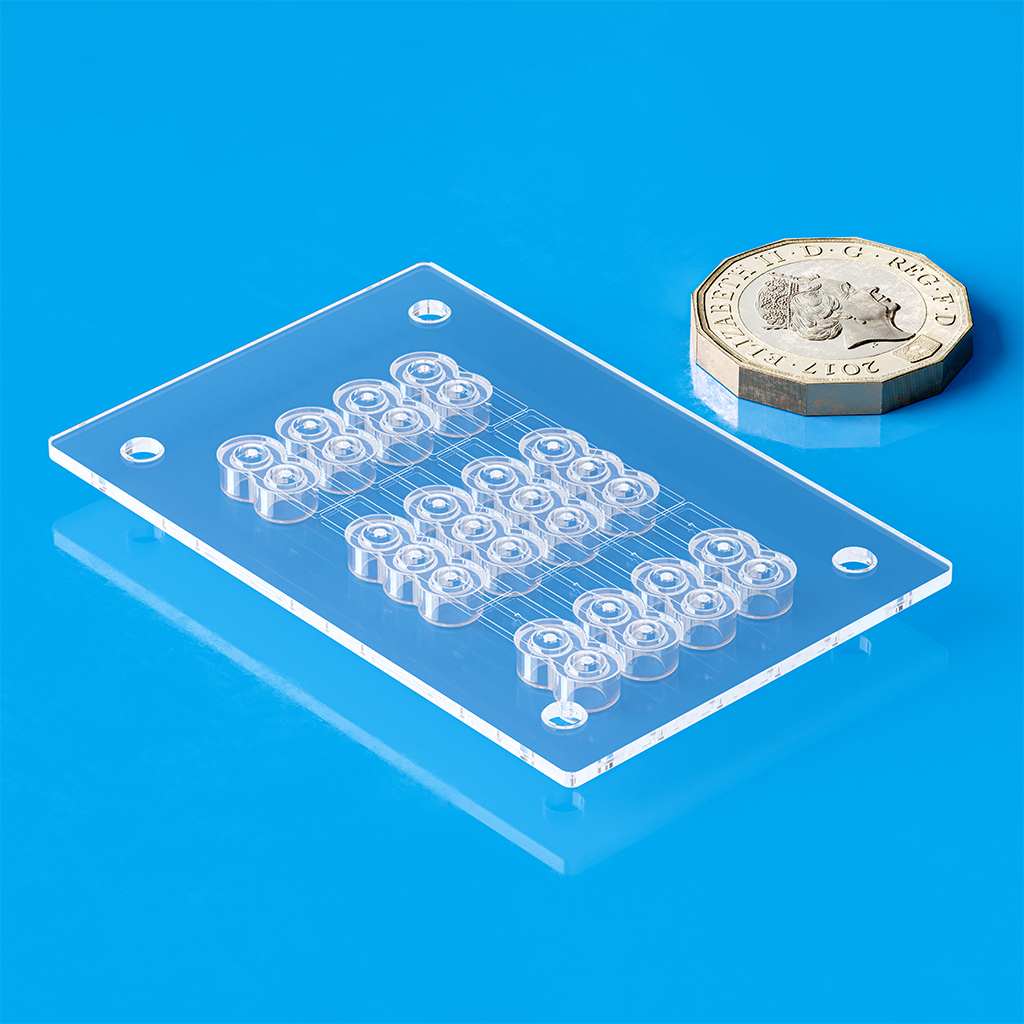

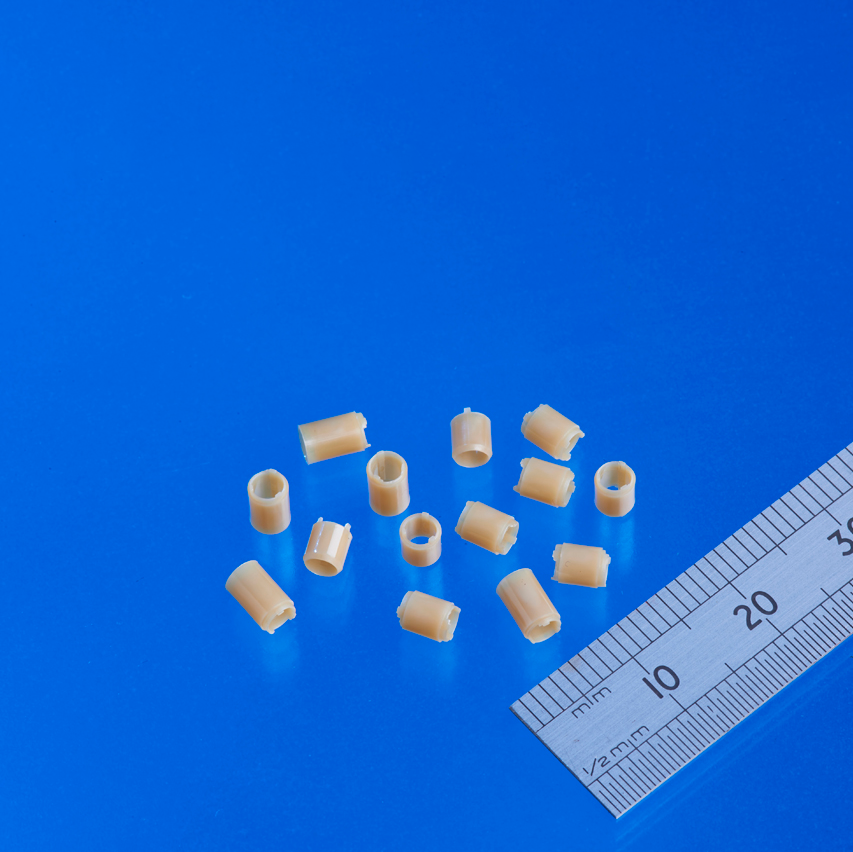

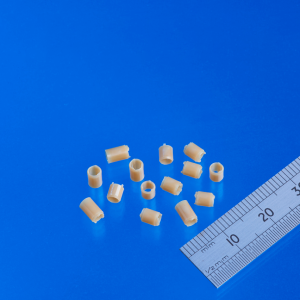

Capillary clamps

Injection pen

Lens packaging

Why choose us?

3 2-Shot Krauss Maffei molding machines. Access to 6 MicroPower 15 Micro Molding machines with Overmold capabilities

24/5 and 24/7 production capability

On-site mold making and micro molding facilities at Micro Systems

Component weights between….. Wall thickness between…. Accuracy between…

High-performance medical grade materials including PEEK, COP,…

Class 7 Cleanroom Injection Molding facilities. ISO:13485 accredited facility

Benefits of Overmolding

Overmolding is a specialized injection molding process that combines two or more thermoplastic materials into a single, integrated component. Overmolding is a complex manufacturing process, but it offers a wide range of valuable benefits:

- Seamless material integration

- Reduced manufacturing time and cost

- Superior durability and bonds

- More complex ergonomics, aesthetics and branding

- Customizable performance and usability

Comprehensive Overmolding solutions

At Optimold, we specialize in custom plastic overmolding backed by decades of experience and in-house mold tooling expertise. Our team combines advanced technology with deep technical knowledge to create seamless bonds between materials—enhancing both the functionality and aesthetics of your components. From mold design to final production, our engineers provide tailored guidance to ensure optimal performance, durability, and compliance with ISO 13485 standards.

- On-site ultra-precision mold tooling from Micro Systems

- Access to 6x MicroPower 15 Micro Molding machines with overmold capabilities

- ISO Class 7 and 8 cleanroom when required

Molding excellent for various applications

Optimold delivers high-quality overmolded components engineered to meet ISO 13485 standards. Overmolding enhances device performance by providing improved grip, sealing, and protection, while reducing assembly steps and potential failure points. Our solutions offer exceptional durability, cost efficiency, and design flexibility—supporting critical medical applications with precision, safety, and reliability.

Synergy to streamline the entire Development and Validation process

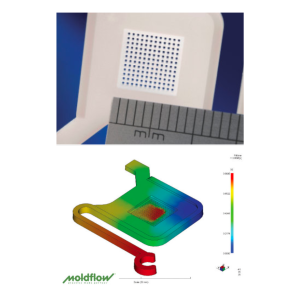

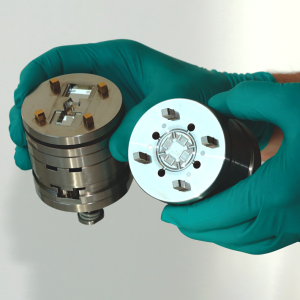

At Optimold and Micro Systems, we deliver complete end-to-end manufacturing solutions that go far beyond standard injection molding services. True success—especially at scale—relies on getting the entire process right from the start. Our projects begin with Design for Manufacturability (DfM) guided by DFMEA, followed by pilot runs using 2-cavity molds to validate design, prove functionality, and catch issues early—reducing risk and cost. Only then do we scale to full production tooling, typically 8, 16, or 32 cavities, enabling efficient, high-volume manufacturing with consistent quality and compliance. This integrated approach ensures your project is built for long-term success.

- DFMEA

- Mold Manufacture

- Mold Testing & Development

- Validation

- Metrology

- Production Molding

Explore other services

Talk to our experts about your Overmolding requirements

Enhance device performance and patient safety with precision Overmolding. Contact our medical molding experts today to bring your innovation to life