High-Precision Metrology for Molds and Components

Metrology excellence from Mold tooling to Injection Molding

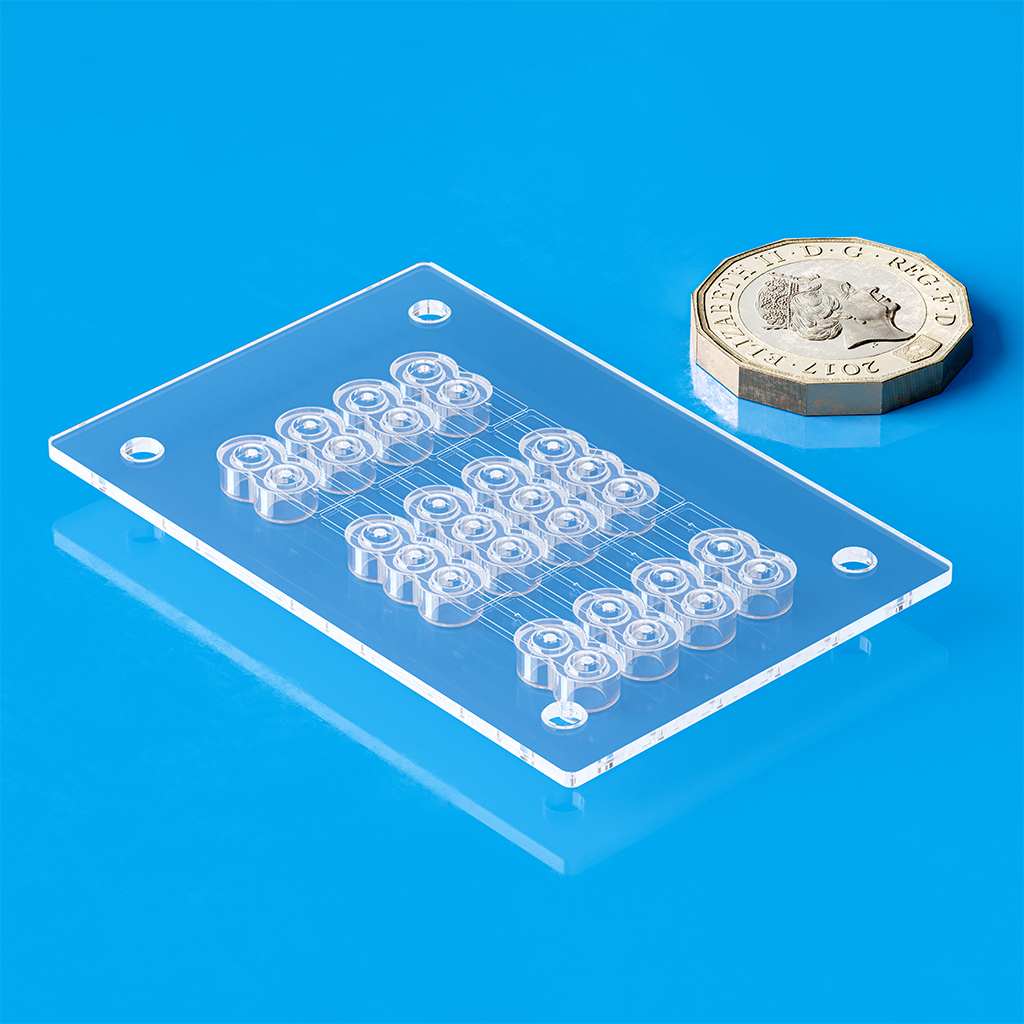

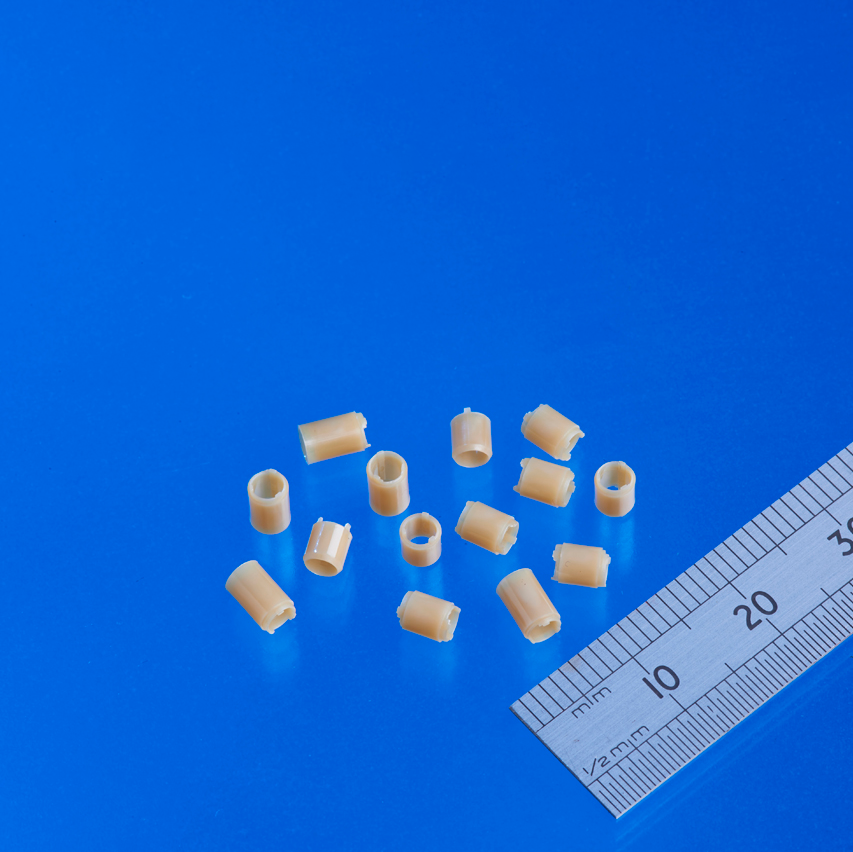

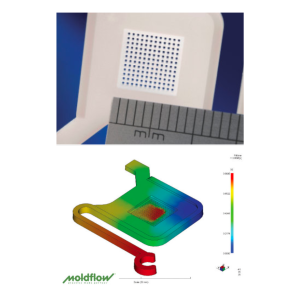

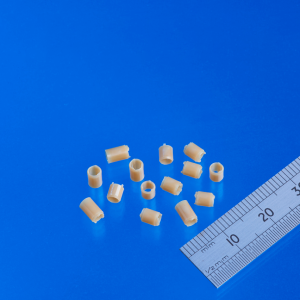

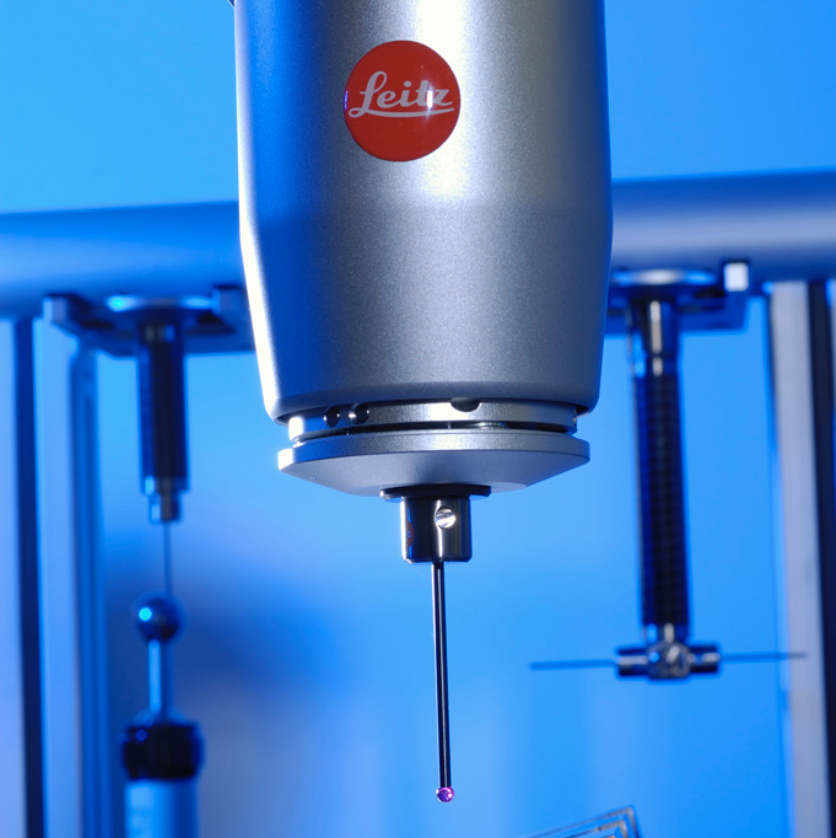

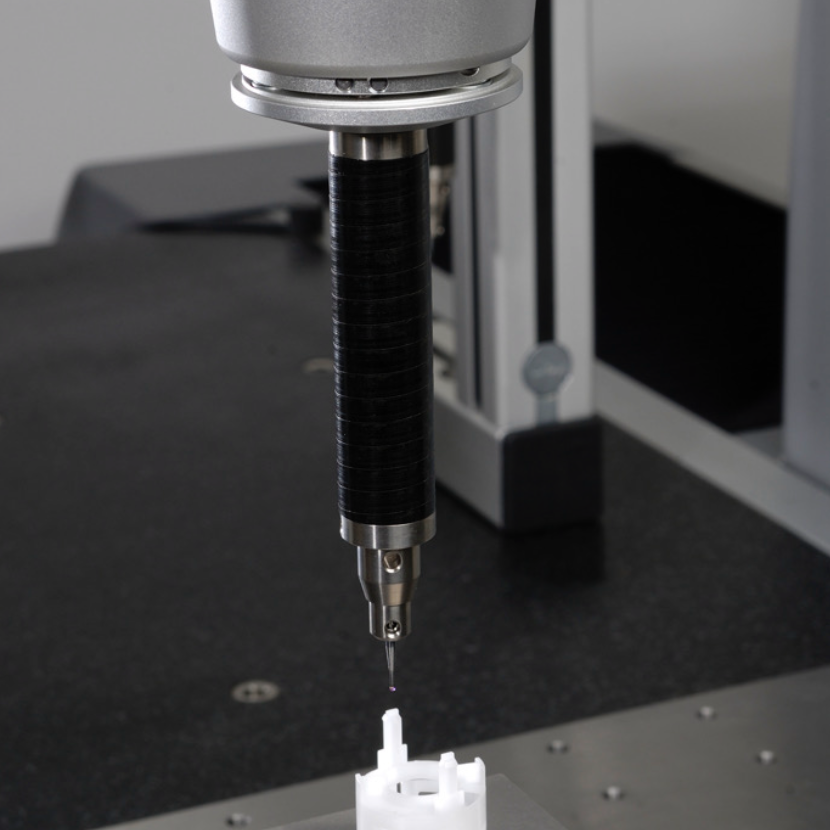

Achieving perfection starts with precise measurement. Our ISO 13485-certified process is backed by over a decade of experience and advanced in-house metrology labs in Optimold and Micro Systems. Equipped with touch probe and vision CMMs, white light interferometry, surface scanning, and CT scanning—all supported by GOM software—we deliver complete, high-accuracy metrology reports. From mold validation to final part inspection, our metrology capabilities ensure every component meets exacting medical and performance standards, optimizing quality at every stage of development.

Extensive Metrology facilities

Achieving perfection starts with precise measurement. With ISO 13485 certification and over a decade of expertise, our metrology labs at Optimold and Micro Systems offer full in-house capabilities. Using touch probe and vision CMMs, white light interferometry, surface scanning, and CT scanning—powered by GOM software—we generate detailed reports with accuracy from ±1 micron to sub-nanometre resolution. From mold validation to final inspection, we ensure every part meets the most demanding medical and performance standards.

- CT Scanner

- White-light interferometers

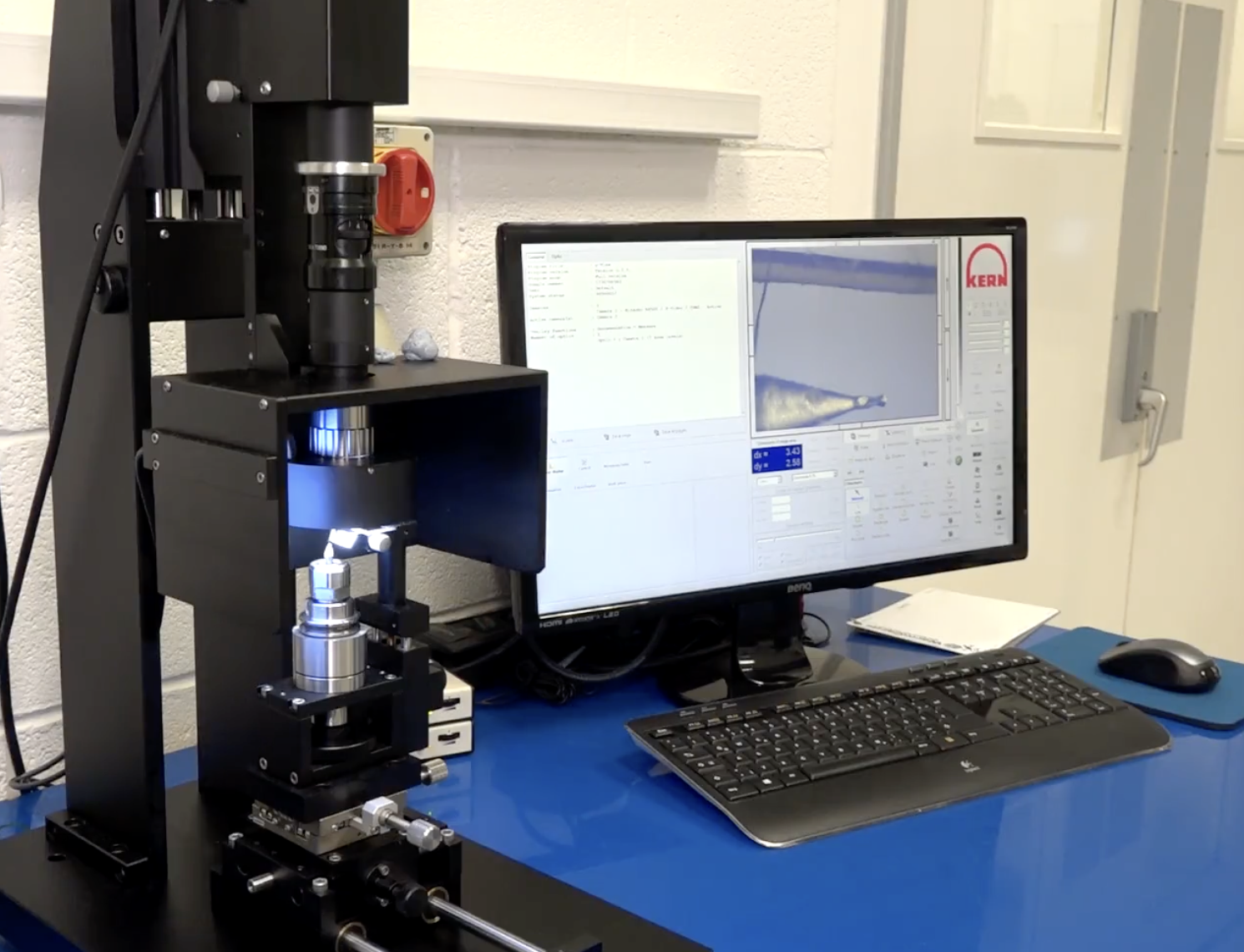

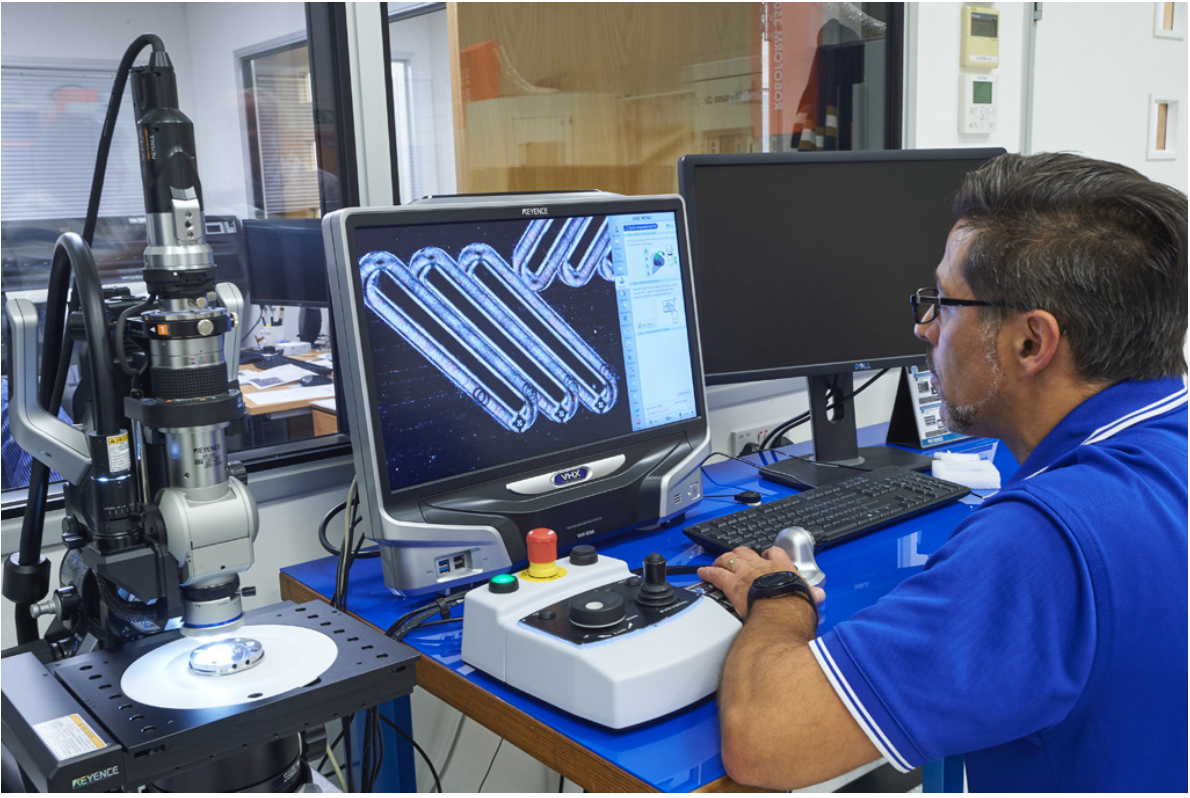

- Vision systems

- Digital Microscopes

- CMM

Precision Metrology for High-Performance Component Development

Synergy to streamline the entire Development and Validation process

- DFMEA

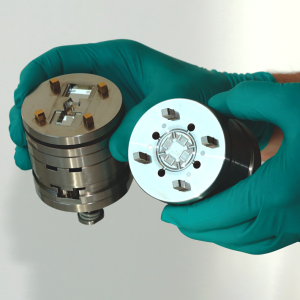

- Mold Manufacture

- Mold Testing & Development

- Validation

- Metrology

- Production Molding