Injection molding is a cornerstone process for producing the high-precision plastic components essential to medical devices, diagnostics, drug delivery systems, and ophthalmic applications. When manufacturing parts for medical use, cleanliness and contamination control are paramount. This is where cleanroom injection molding becomes indispensable.

What is Cleanroom Injection Molding?

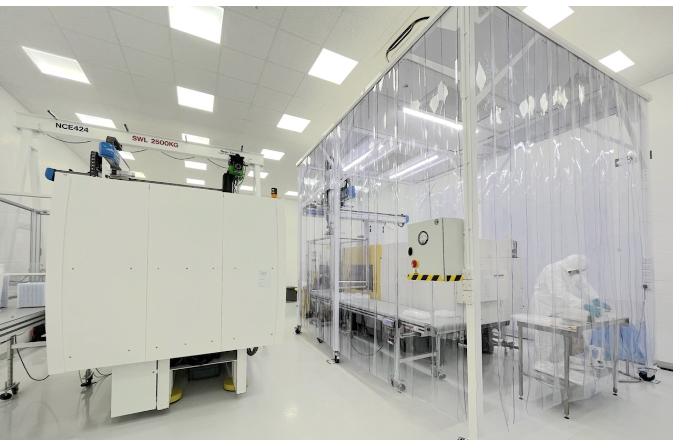

Cleanroom injection molding is the process of producing plastic components within a controlled environment that limits airborne contaminants such as dust, microbes, and chemical vapors. These environments adhere to strict cleanliness standards defined by ISO classifications (commonly ISO Class 7 or 8 for medical manufacturing).

The setting ensures that medical-grade plastic parts meet rigorous quality, safety, and regulatory requirements by reducing contamination risks during molding.

Why Cleanroom Molding Matters for Medical Devices

Medical devices often have direct or indirect contact with patients, requiring them to be sterile or near-sterile. Contamination can compromise device safety, effectiveness, and regulatory compliance. Cleanroom molding provides:

- Minimized Part Contamination: Controlled airflow and filtration systems reduce particle presence.

- Regulatory Compliance: Aligns with ISO 13485 and FDA requirements for manufacturing environments.

- Improved Product Reliability: Reduces defects caused by contamination such as surface blemishes or biofilm formation.

- Support for Complex Components: Enables molding of sensitive parts like microfluidic chips, intraocular lenses, and implantable devices.

Key Features of Medical Cleanroom Injection Molding

- ISO Classified Environments: Most medical cleanrooms operate under ISO Class 7 or 8, ensuring strict limits on airborne particles.

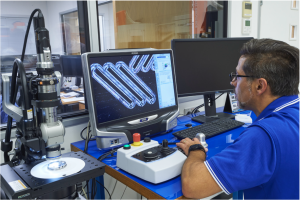

- Validated Processes: Regular testing and monitoring maintain cleanroom integrity and process consistency.

- Specialized Equipment: Injection molding machines equipped with sterile tooling, robotic handling, and enclosed systems to avoid human contamination.

- Material Handling Protocols: Strict controls for biocompatible materials and sterilization procedures.

Cleanroom Injection Molding at Optimold

Optimold’s UK-based facility incorporates ISO 13485-certified cleanroom molding capabilities, including ISO Class 7 and 8 environments tailored for medical manufacturing. Our processes encompass rigorous validation, comprehensive metrology, and contamination control measures to ensure each component meets stringent quality and regulatory standards. By combining the technology with precision injection molding, Optimold delivers critical medical components that support patient safety and accelerate time to market.

Cleanroom injection molding is a vital process in the manufacture of medical devices, ensuring that components are produced in an ultra-clean environment compliant with strict regulatory standards. By investing in advanced cleanroom facilities and validated processes, manufacturers like Optimold help medical device OEMs meet the demanding requirements of modern healthcare applications with reliability and confidence.

Contact us today!