Contact lenses are marvels of medical engineering—tiny, transparent devices that require extreme precision to safely and comfortably correct vision. Behind every contact lens is a highly specialized mold, manufactured to sub-micron accuracy. But how are these molds made, and what does it take to ensure their performance and consistency at high volumes?

In this article, we’ll explore how contact lens molds are produced, especially for daily disposables and advanced soft lenses, focusing on precision tooling, material selection, and high-volume injection molding processes.

Why Molding Matters in Contact Lens Production

Most contact lenses, especially soft hydrogel or silicone hydrogel lenses, are produced using a cast molding process. In this process, the liquid lens material is poured between two precision molds—one forming the front curve, the other forming the back curve of the lens. After curing (often by UV light or heat), the lens is hydrated, extracted, and packaged.

Because the mold directly defines the optical power, shape, and surface finish of the lens, the accuracy and quality of the mold are absolutely critical. Even a micron-level deviation can affect lens performance or comfort.

Step 1: Ultra-Precision Mold Tooling

The first stage is to manufacture the injection mold tool—a steel or aluminum block that contains cavities for producing thousands or millions of individual plastic molds.

Key characteristics of contact lens mold tooling include:

- Sub-micron accuracy (often better than ±0.5 µm)

- Ultra-smooth optical surfaces (<10 nm Ra)

- Perfect concentricity and alignment between mold halves

- High-precision venting and ejection features for consistent molding

To achieve this, advanced micro milling and diamond turning are used, often on machines like the Kern Pyramid Nano or Moore Nanotech. CAD and CAM software, such as Siemens NX, are used for mold design, often integrated with optical simulation tools to model lens geometry and light behavior.

Step 2: Injection Molding of the Mold Halves

Once the tool is ready, the next step is injection molding of the disposable contact lens molds. These are usually made from transparent polymers like polypropylene (PP) or polystyrene (PS), which must meet high clarity, dimensional, and biocompatibility standards.

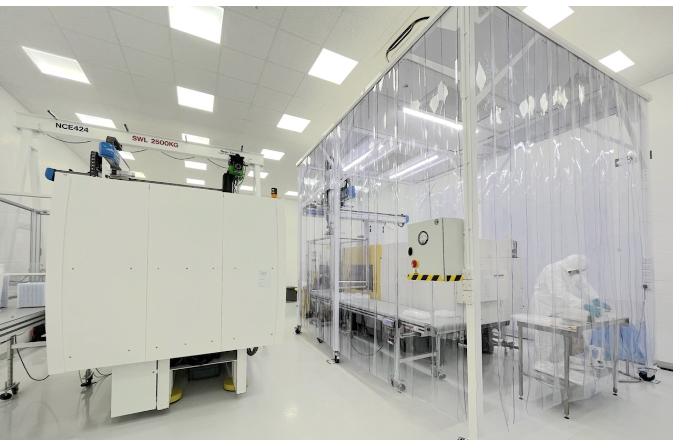

The injection molding process typically takes place under controlled cleanroom conditions to prevent contamination of the mold surfaces.

Key process parameters include:

- Cycle time optimization for high-volume production

- Precise temperature and pressure control

- Mold flow analysis to ensure even filling and venting

- Optical inspection to check for surface defects, warping, or distortion

Step 3: Quality Assurance and Metrology

Because the mold determines the optical power of the final lens, rigorous metrology and inspection are required. Tools like:

- Contact and non-contact profilometry

- 3D laser scanning

- Interferometry

- CT scanning for mold geometry

…are used to validate that every mold cavity meets spec. At scale, automated vision systems check every batch, and traceability is enforced under ISO 13485 and GMP guidelines.

Why It’s So Challenging

Making contact lens molds is particularly difficult because:

- The molds are disposable, meaning millions are needed annually.

- They must be optically perfect, despite being mass-produced.

- They require cleanroom-grade manufacturing with zero contamination.

- The mold tooling itself must last through millions of cycles without degradation.

These demands push the limits of precision engineering, requiring a combination of ultra-precision machining, high-performance plastics, validated molding processes, and metrology all working together.

At Micro Systems and Optimold

At Micro Systems and Optimold, we specialize in the design and manufacture of contact lens molds, offering:

- Ultra-precision mold tooling with sub-micron accuracy

- Injection molding of contact lens casts and packaging in ISO Class 7 cleanrooms

- Validated production processes compliant with ISO 13485

- Extensive metrology and process control systems

- Experience with global ophthalmic OEMs

Together, our UK and Singapore facilities offer 24/5 and 24/7 capabilities for supporting both development and large-scale production.

Making contact lens molds is a masterclass in precision manufacturing. It’s where optics, micro-mechanics, polymer science, and automation all come together to produce the small, reliable, and comfortable lenses that millions of people use daily.

If you’re developing ophthalmic devices or packaging that require similar levels of precision, choosing the right manufacturing partner is key.

Contact us today!