ISO 13485 Injection Molding for Microfluidic Diagnostics applications

Optimold offers precision injection molding for microfluidic diagnostics, with ISO 13485 certification and 15+ years of experience. In partnership with Micro Systems, we deliver ultra-precise replication of microfluidic features—down to 0.5 microns—using advanced polymers like PC, COC, and COP. Work with us to reduce development time while ensuring consistent, high-quality performance in microfluidic chips—fully optimized for reliable high-volume production.

Precision Molding for Microfluidic Diagnostics Breakthroughs

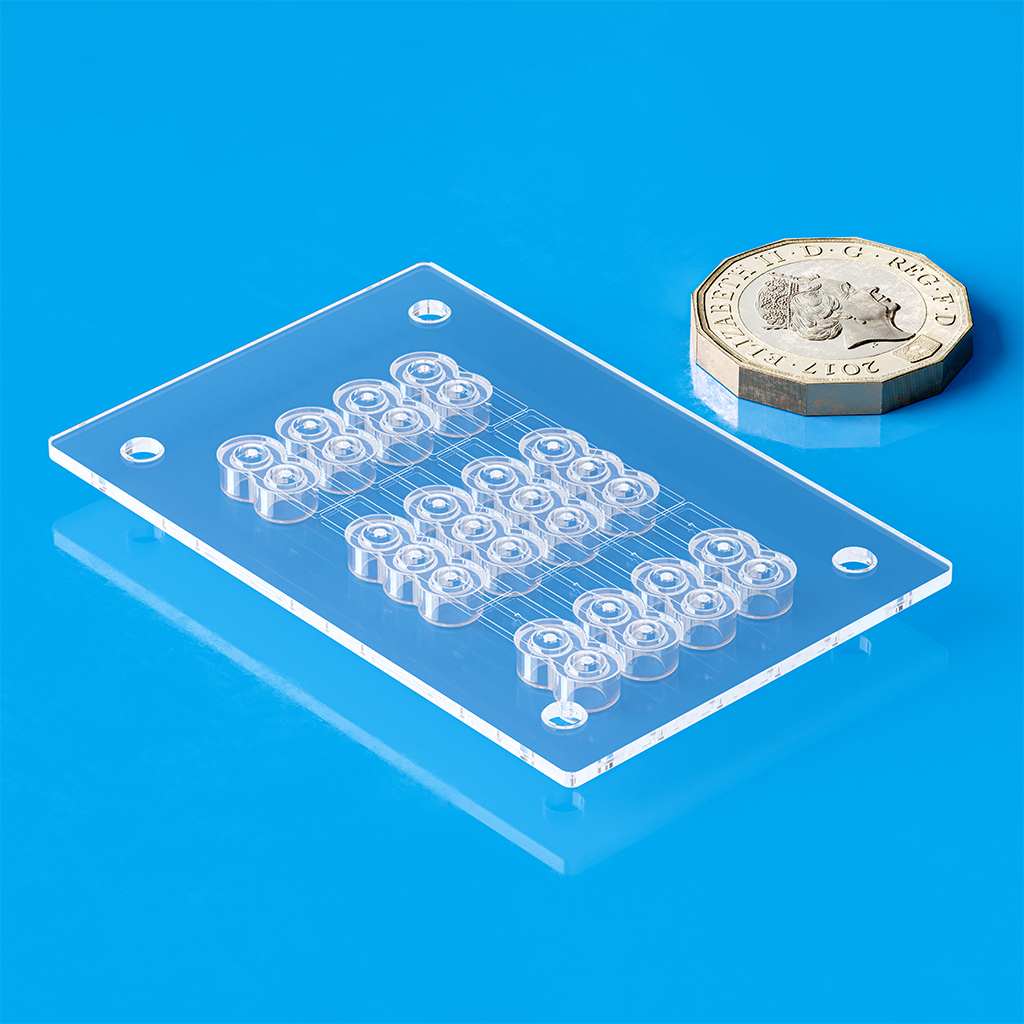

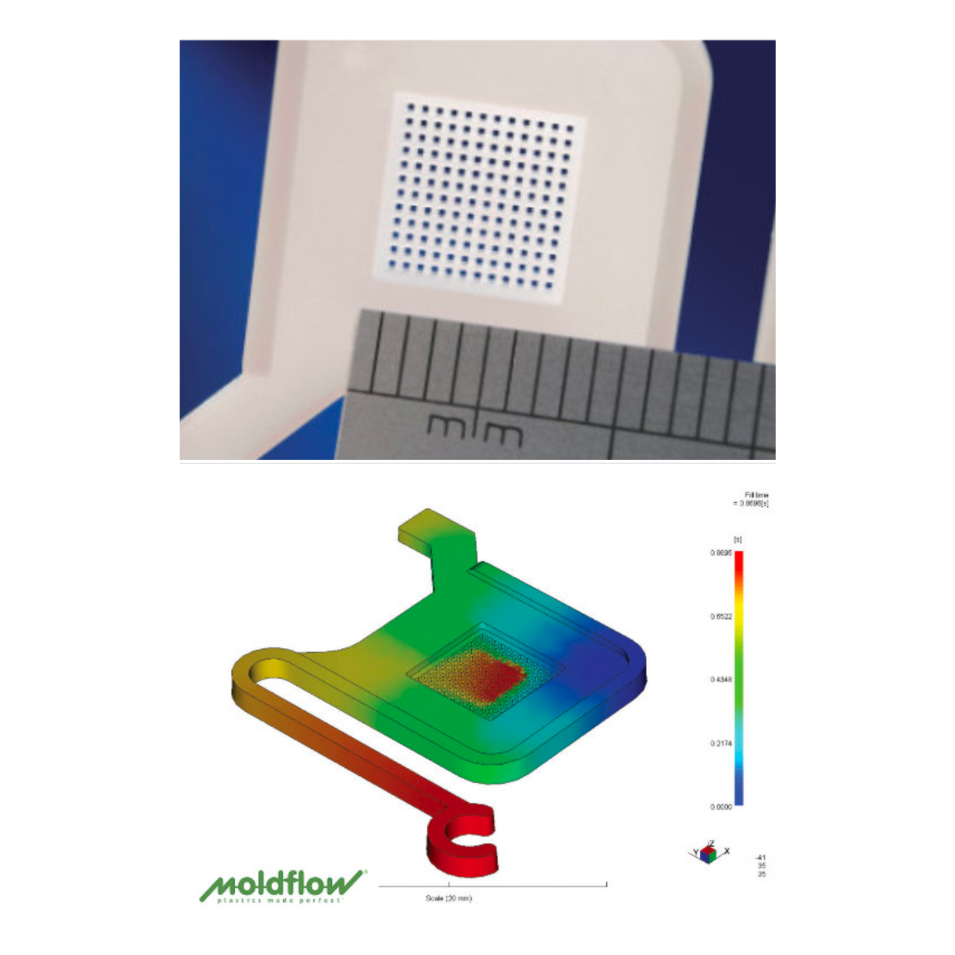

Optimold is one of the few industry leaders capable of high-volume injection molding of complex microfluidic diagnostics components—up to one million units—with feature sizes below 10μm and repeatability within 0.5μm. This precision is critical for capillary-driven functions like cell selection, droplet mixing, and generation.

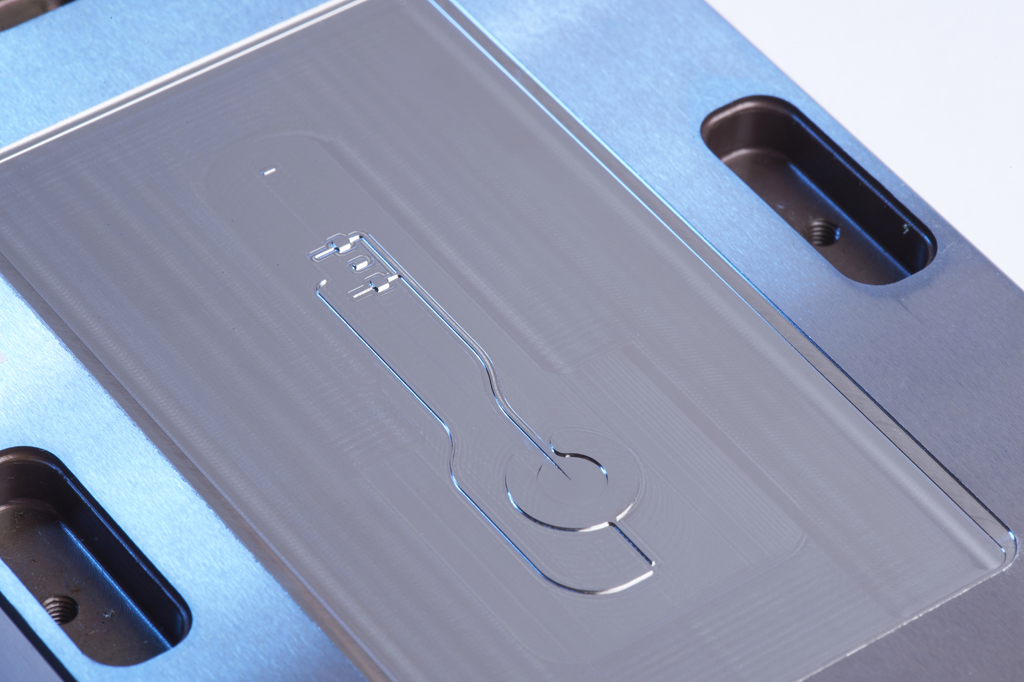

In collaboration with our mold tooling partner, Micro Systems, we achieve micron-level flatness and ultra-fine features. Their Integrated Optics technology enables optical surfaces with sub-10nm Ra finishes, directly within the microfluidic chip—ensuring continuous capillary flow and 100% chamber filling.

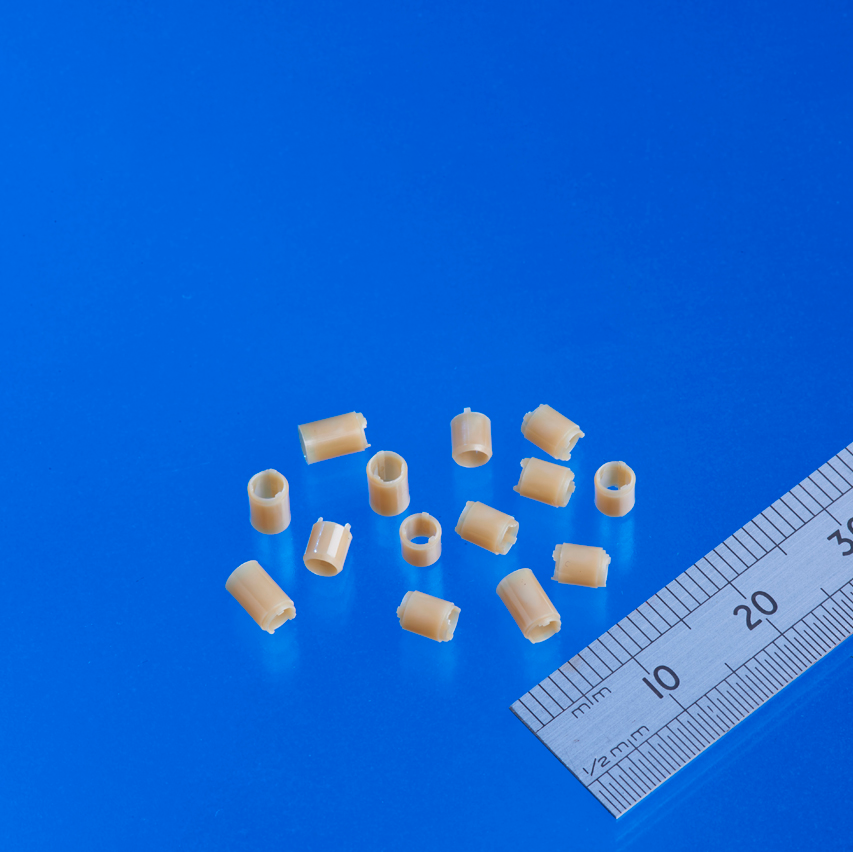

Microfluidic Diagnostics Injection Molding examples

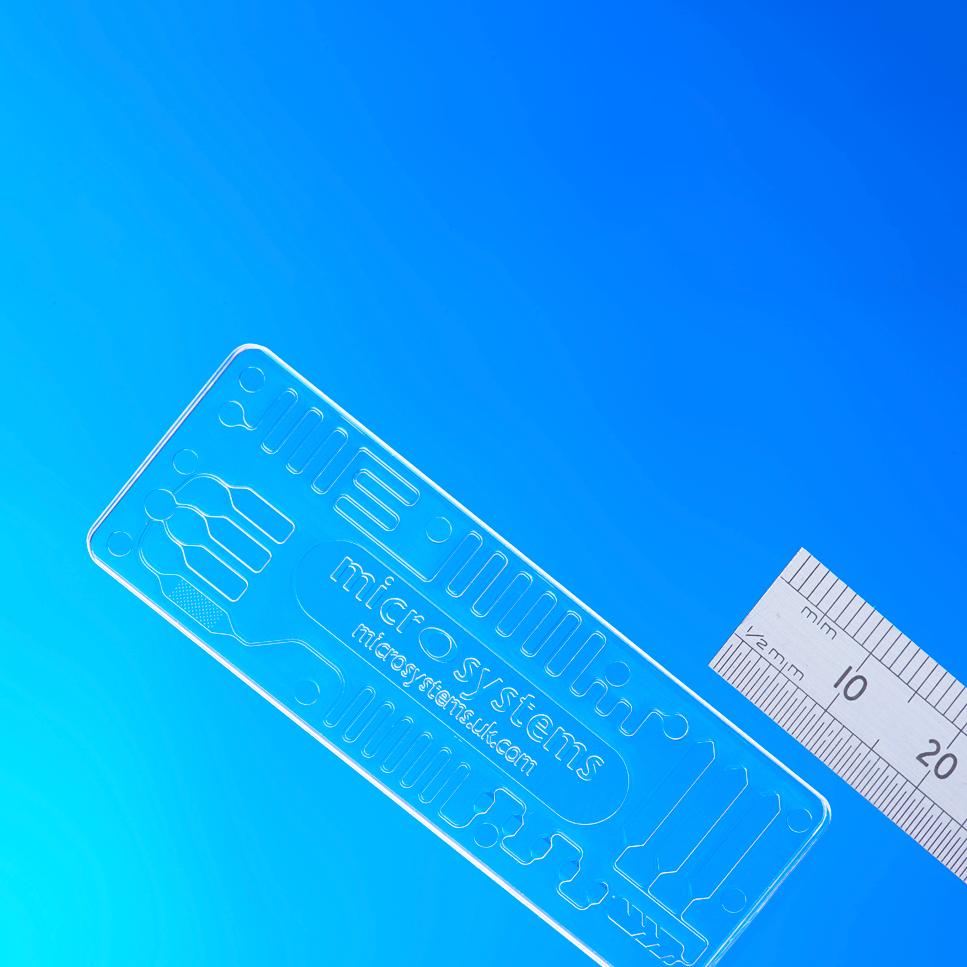

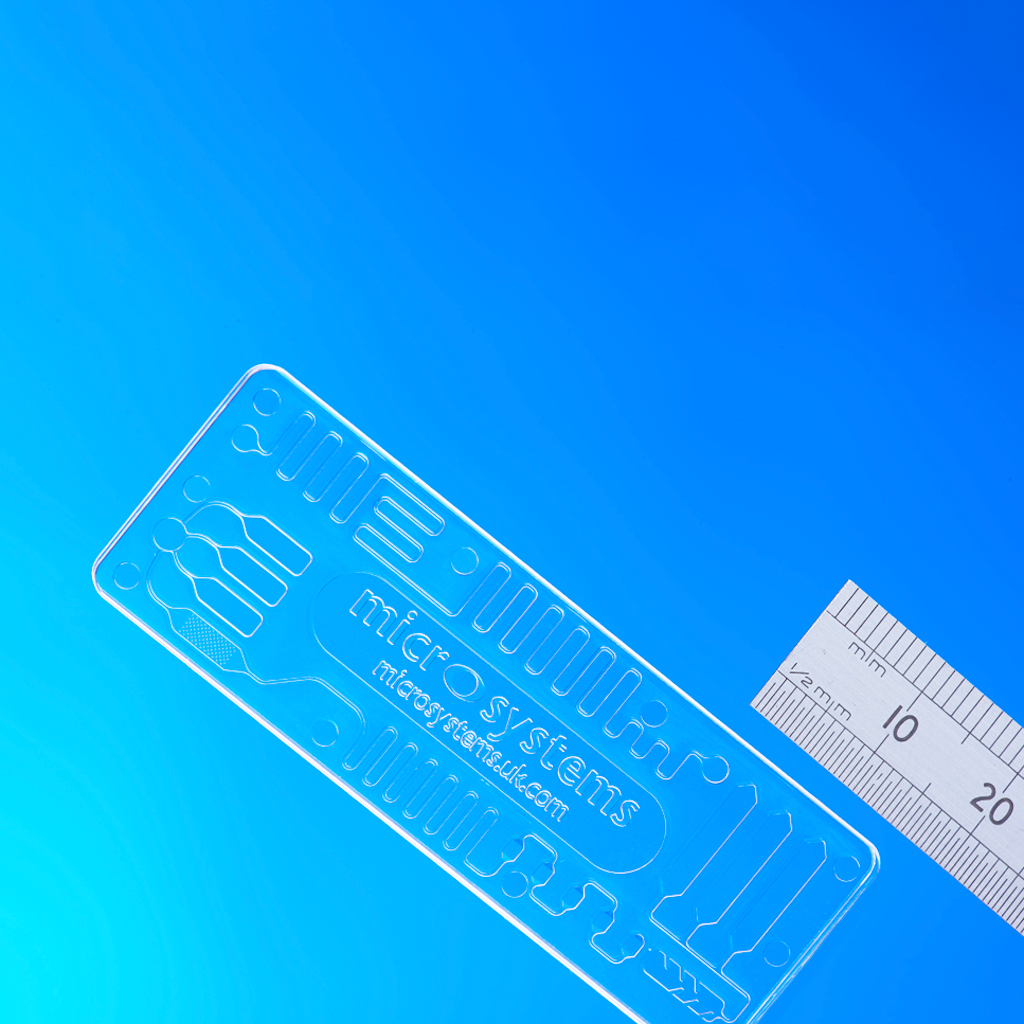

Blood analysis of….mm, made of…., enabling rapid, precise, and low-volume testing for faster, point-of-care diagnostics.

Blood analysis of….mm, made of…., enabling rapid, precise, and low-volume testing for faster, point-of-care diagnostics.

Ultimate machining achievements

The co-location of all business functions on one site enables Micro Systems and Optimold to offer a service to our customers unrivalled by any of the other key players in the industry.

- Extensive experience and expertise in all areas creates synergy across functions from DFM to molding

- Seamless communication

- Fast mold development

- Immediate availability of production support

Integrated optical faces

Integrated optical interfaces are critical in microfluidics, as the absence of seamless optical integration can disrupt the flow of blood or cell-containing fluids, potentially compromising the accuracy of test results. Our capabilities in Mold Design and injection molding enable the continuous capillary flow required to guarantee 100% filling of inspection chambers prior to optical laser detection using Frustrated Total Internal Reflection (FTIR) to detect the presence of magnetic nanoparticles. Further extensive research of tool insert materials, processes and molding techniques allow our Integrated Optics, traditionally machined in Nicke inserts, to be machined in hardened stainless steel (50Rc) to support high volume component molding requirements.

Beyond Microfluidic Diagnostics Injection Molding

Optimold provides industry-leading customer service and support for your Microfluidic Diagnostics projects, including:

- Precision Injection Molding: high-precision molding, 2K-molding, …

- A range of high-performance engineered materials: PEEK, ABS,…

- Scalable solutions: from small lot to multi-million unit batches

- In-house tooling: ultra-precision mold (single and multi-cavity, micro mold)

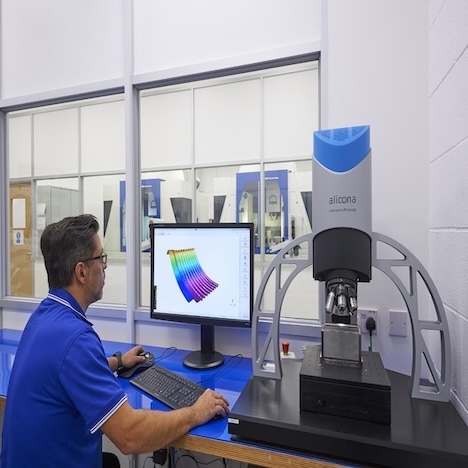

- Quality Management: Validation services: FAT to full IQ, OQ, PQ – Mold testing and evaluation

- Extensive Metrology capabilities

Explore other applications

Talk to us about your Microfluidic Diagnostics project

Ready to accelerate your Microfluidic Diagnostics production with precision and efficiency? Partner with Optimold for ISO 13485-certified, cleanroom injection molding and integrated tooling solutions.