Precision Molding solutions for Ophthalmic Devices

Optimold delivers precision injection molding for ophthalmic devices, backed by 15+ years of experience and ISO 13485 certification. Our cleanroom facilities ensure optical-grade quality, while our tooling partner, Micro Systems, enables fast, high-precision toolmaking. We help bring vision-critical products to market with speed, accuracy, and full regulatory compliance.

ISO 19485 Ophthalmic Injection Molding Solutions

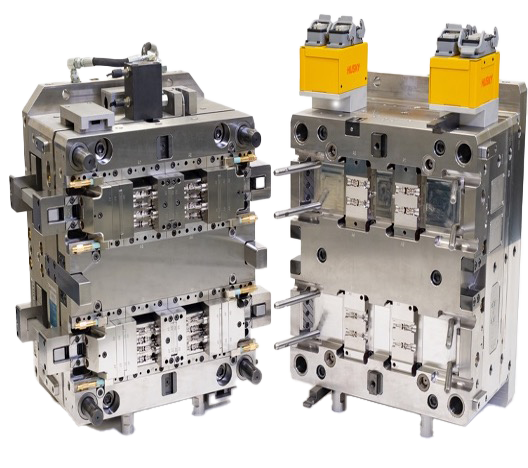

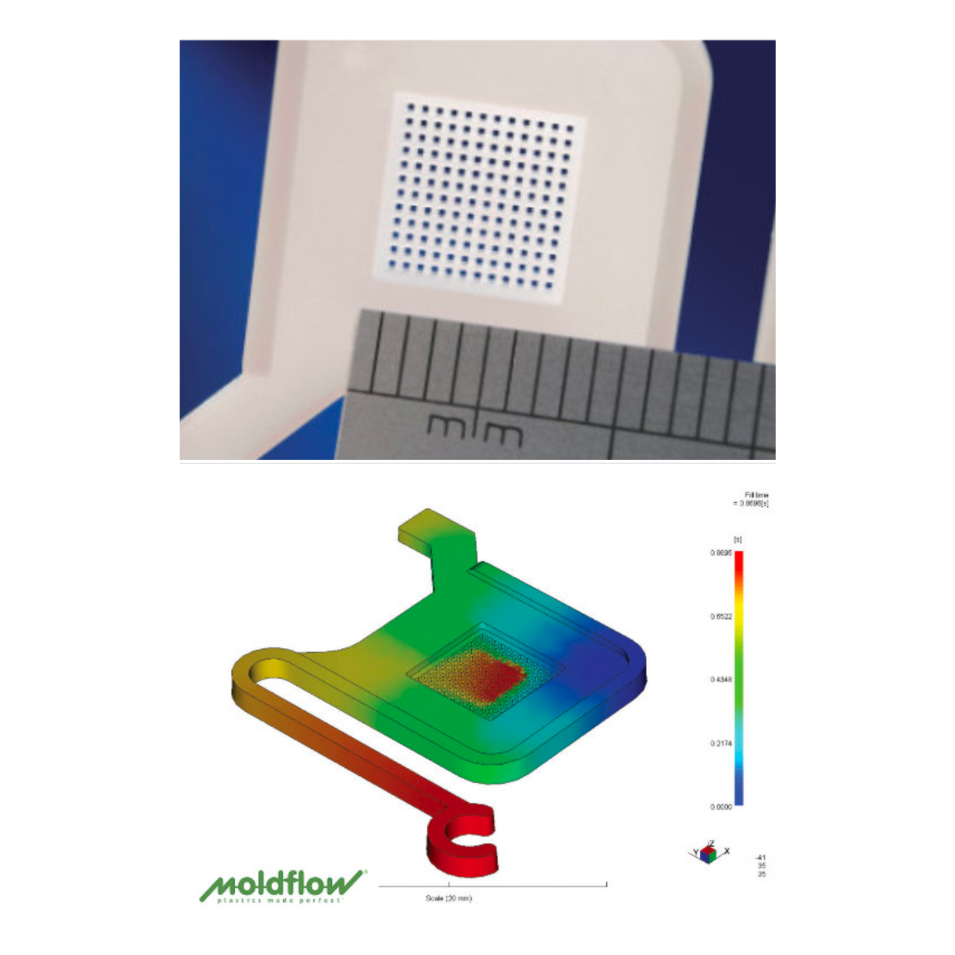

Optimold specializes in precision injection molding for ophthalmic devices, including Class I, II, and III components. Our in-house tooling enables complex micro features, tight shutoffs, and minimal flash for superior part quality. ISO 13485 certified, we ensure clean, reliable production with proven regulatory compliance and on-time delivery. Our capabilities include:

- Ophthalmic moulding

- Contact Lens Casts

- Contact Lens Packaging

- IOL Casts

- Integrated optical windows for microfluidic diagnostic chips

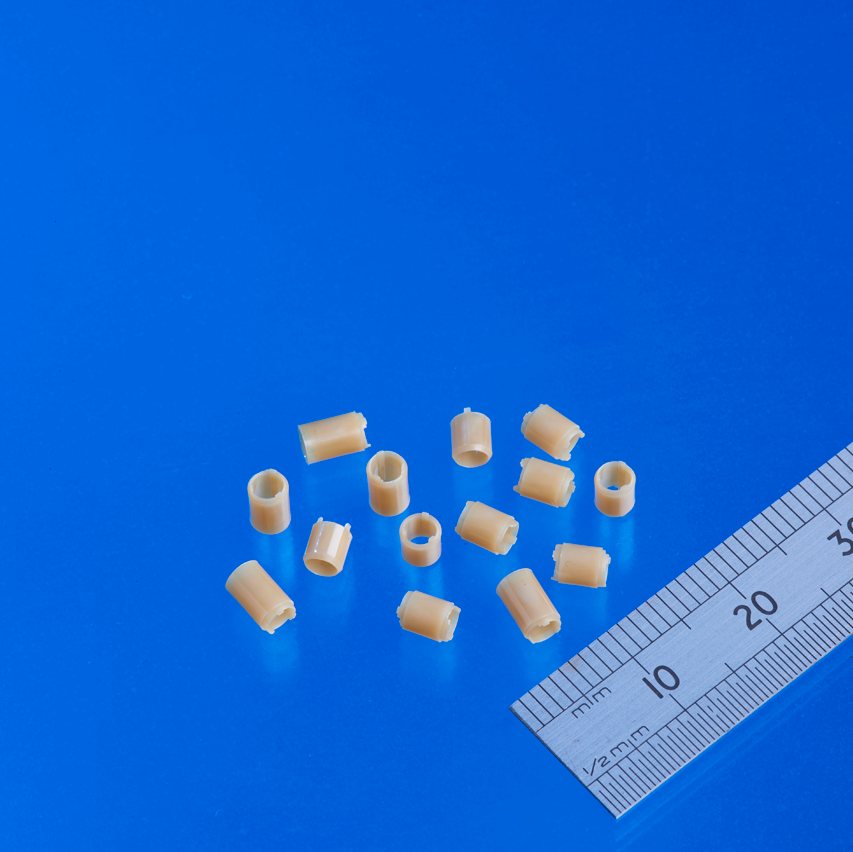

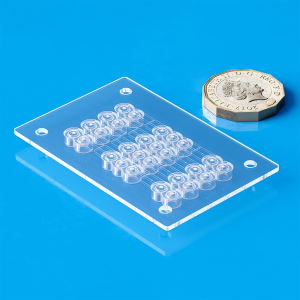

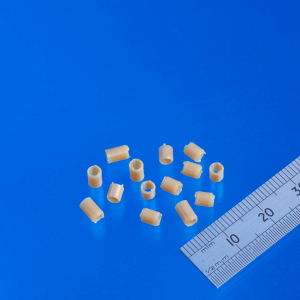

Ophthalmic Injection Molding examples

Contact Lens Packaging of…

Contact Lens Packaging of…

Scalable Ophthalmic Production

When precision, optical clarity, and cleanliness are critical, Optimold is your trusted partner in ophthalmic device manufacturing. From small development batches to multi-million-unit production runs, our in-house tooling capabilities with Micro Systems enable rapid, flexible manufacturing with fast turnaround times. We deliver high-precision ophthalmic applications, featuring novel mold designs with precise shutoffs, intricate micro features, and minimal flash—ensuring the quality and performance required for vision-critical devices. ISO 13485 certified, we meet stringent regulatory standards while supporting you throughout the entire product lifecycle.

Beyond Ophthalmic Injection Molding

Optimold provides industry-leading customer service and support for your Ophthalmic Molding projects, including:

- Precision Injection Molding: high-precision molding, 2K-molding, …

- A range of high-performance engineered materials: PEEK, ABS,…

- Scalable solutions: from small lot to multi-million unit batches

- In-house tooling: ultra-precision mold (single and multi-cavity, micro mold)

- Quality Management: Validation services: FAT to full IQ, OQ, PQ – Mold testing and evaluation

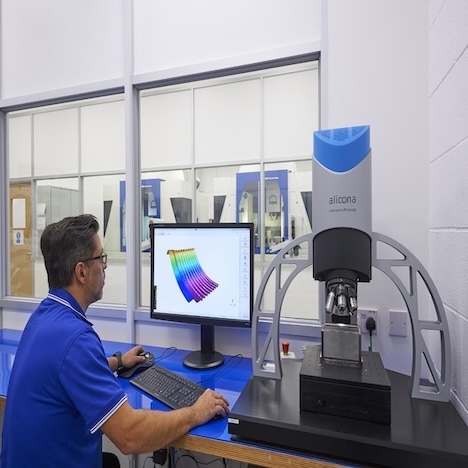

- Extensive Metrology capabilities

Explore other applications

Talk to us about your Ophthalmic Molding project

Ready to accelerate your ophthalmic device production with precision and efficiency? Partner with Optimold for ISO 13485-certified, cleanroom injection molding and integrated tooling solutions.