Advanced Technologies for Precision Medical Injection Molding

Based in Warrington, UK, our advanced manufacturing facilities feature ISO Class 7 and Class 8 cleanrooms, designed for 24/5 and 24/7 operation. We offer ISO 13485-certified cleanroom injection molding, delivering high-precision solutions across the full production spectrum—from low-volume to large-scale multi-million manufacturing. Supported by sophisticated metrology systems and comprehensive validation protocols, including FAT, IQ, OQ, and PQ, we ensure full compliance with regulatory requirements and the highest standards of quality and performance.

16

Injection Molding Machines

300

Tons Injection Molding Machines

500

m2 Cleanroom

Injection Molding

Operating within an ISO 13485-certified environment, we offer molding in a Class 7 cleanroom for critical medical components. Our facilities are equipped with hydraulic and all-electric injection molding machines ranging from 30 to 300 tonnes, including twin-shot molding capabilities for complex, multi-material parts. Robotic handling and automated packing systems further enhance efficiency, consistency, and cleanliness throughout the manufacturing process.

- Injection Molding Machines From 30t to 300t

- Hydraulic and all-electric moulding machinery

- Twin-shot moulding capabilities

- Robotic handling and packing facilities

- 24/5 and 24/7 production capability

- Class 7 and 8 cleanroom facilities

Metrology

Our advanced metrology ensures precision and regulatory compliance at every stage, using CNC vision and touch CMMs for high-accuracy inspections. These tools support full mold validation, from factory testing to IQ, OQ, and PQ, meeting the strict demands of the medical industry.

Our extensive Metrology facilities are capable from +/- 1 micron down to sub-nanometre resolution:

- CT Scanner

- White-light interferometers

- Vision systems

- Digital Microscopes

- CMM

High-performance medical-grade materials

As healthcare advances, high-performance medical-grade plastics are vital for surgical tools, drug delivery, diagnostics, and implants. At Optimold, we select specialized thermoplastics tailored for medical and pharmaceutical needs, balancing strength, compliance, sterilization, and chemical resistance to ensure safe, high-quality devices that enhance patient outcomes.

Our range of materials include: PEEK, ABS, HDPE, LCP, LDPE, PS, PC, PBT,… and others on request.

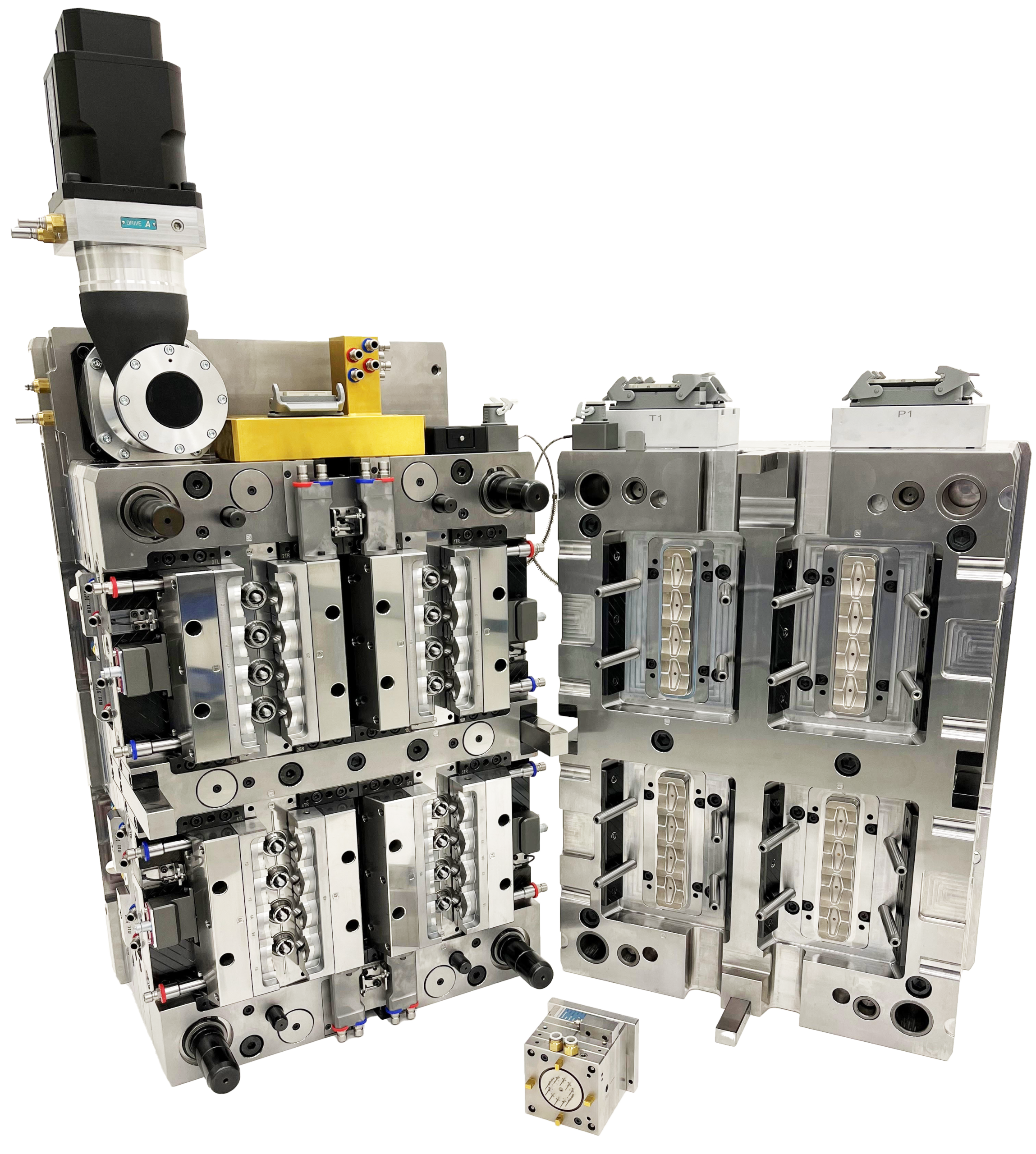

In-house Mold Tooling

As a turnkey injection molding partner, in-house mold tooling is at the heart of our integrated operations. Through our sister company, Micro Systems—specialists in ultra-precision and micro mold tooling with over 22 years’ experience—we provide direct access to advanced mould design and manufacturing. Accredited to ISO 9001 and ISO 13485, Micro Systems guarantees the highest quality and compliance for industrial and medical applications. This close partnership enables rapid mould development, seamless communication, and swift production support, enhancing flexibility and accelerating time-to-market.

- Ultra-precision Injection Mold

- Micro Mold

- Multi-cavity Injection Mold

Let’s get in touch

Experience the difference with our cutting-edge injection molding technologies—designed to help you achieve unmatched precision, faster production, and consistent quality.